The best way to optimise compressed air costs is to identify where the most significant usage exists and regulate it. A key area for optimisation is in the mine air supply for underground refuge facilities. Running unregulated compressed air directly into a permanent refuge bay full time is common practice in South Africa. Not only is this practice hazardous, but it is also very wasteful.

One key demand for many mining operations’ power supply is compressed air. Compressed air is used on many underground sites both to power tools and also to ventilate mine shafts. As compressed airline systems can be complex and wastage can occur due to a wide range of factors, optimising compressed air on a mine site is an essential and very effective way to reduce a company’s bottom line dramatically.

MineARC has developed a Compressed Air Management System (CAMS) Flushing Airlock explicitly designed for permanent refuge shelters in the South African market to address safety concerns and rising compressed air costs.

Power Costs Spike for South African Mines

News from South Africa’s electricity supplier Eskom is planning, yet another price increase of 9.4% this month has put the mining industry under further pressure.

Eskom’s price augmentation has been relentless and far beyond South Africa’s inflation markers for several years now. Load sharing was introduced in 2008 to alleviate demand on South Africa’s under-prepared grid. Since then, Eskom continues to raise the price of power, in real terms, by a staggering 78%. Yet, price hiking did not stop there. From 2011, Eskom annually increased power prices far beyond CPI for both domestic and industrial markets. Between 2013 and 2015, the average price increase per annum has been 12% (8% for domestic and 13% for mining).

There does not appear to be any regulatory control over Eskom’s price hikes. Over and above the stagnant investor market and the deflated commodity prices, the mining industry has had to look inwards for savings and optimisation to survive the cost increases. Many mining leaders, such as Anglo America, are frustrated. They see previous successful cost-cutting efforts yet again swallowed up by the added costs this most recent announcement will incur.

Compressed Air Controls Cost and Wastage

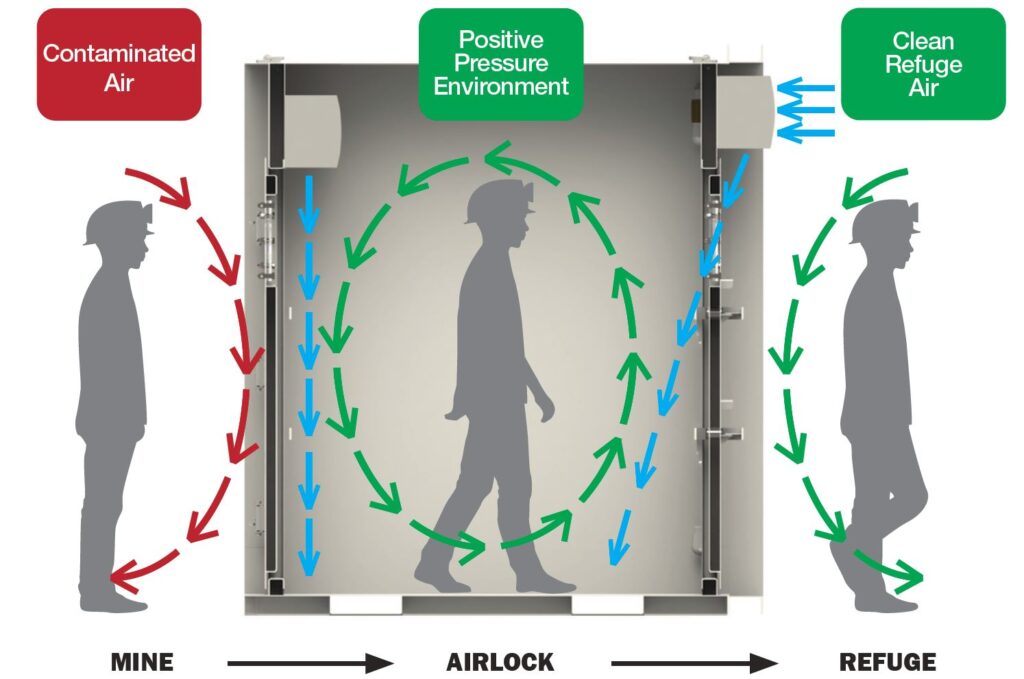

The airlock enables the refuge bay to be a sealed, controlled environment, ensuring smoke or toxins cannot enter the chamber. The combined use of an airlock with CAMS flushing provides two significant benefits.

First, the CAMS Flushing Airlock regulates and purifies compressed air going into a permanent refuge bay while at the same time sealing off the refuge from the ingress of potentially harmful contaminants during an emergency.

Secondly, CAMS regulates airflow, allowing the airlock to maintain positive pressure without excessive compressed air wastage. When measured over a year, CAMS demonstrates savings of up to 90% of air costs per refuge. On larger mine sites, this amounts to considerable financial savings.

Benefits of Filtering Compressed Mine Air

Aside from compressed air management, one benefits of CAMS is its four-stage filtration process. Unfiltered compressed air can be highly hazardous to occupants’ health during an emergency. Even if the airline is not compromised, hydrocarbons, oil vapour, and dangerous particles from diesel fumes and other sources can be drawn in through the compressed air intake and condensed to dangerous levels within the refuge.

Also, an air toxicity monitor and a safety shut off valve. The system monitors oxygen levels in the compressed air and measures the displacement of oxygen by other gasses. If O2 falls below standard levels, the safety shut off automatically activates, ensuring occupants’ safety from toxic gas ingress through the airline.

Once occupants have passed through the airlock and entered the refuge area, mine air is then diverted into the main chamber, enabling occupants to benefit from CAMS’ unique operational features.

It is rare for a product to offer improved safety and dramatic cost savings; however, MineARC’s CAMS Airlock Flushing System does just that. Not only does the system pay for itself in a short period, but it then continues to put more money back into the mine sites pocket by reducing costs. At the same time, it provides peace of mind that they provide their workers with state of the art safety equipment.