What are the fundamental passive fire protection solutions offered for refuge chambers?

Fire dangers exist in underground mining and tunnelling operations. These fires’ heat transfer properties into underground refuge chambers depend significantly on both the fire and the chamber’s position.

Rating Refuge Stations for Fires

It is difficult to give a fire rating to a chamber due to two main factors; the changing environment of its position and the fire risk’s mobile nature.

Therefore, the current refuge chambers design protects against breathing contaminants and lack of oxygen, but not excessive heat load over a long duration.

MineARC refuge chambers have a minimum duration, including the uninterruptible power supply (UPS) and breathing contaminant scrubbing, of 36 hours. This figure is based on rubber tyres’ burn time and a large mining vehicle’s fuel load. These types of fires are accepted examples of mining operation risks.

The positioning of a chamber is critical. A standard refuge chamber (Standard Design or Compact Design) will not sustain life within the shelter if ambient conditions exceed 47°C. Calculations on how the refuge stations are position depend almost solely on the ambient conditions. Upgrades for higher ambient conditions are available.

Fire and Refuge Chamber Positioning

MineARC is unable to produce a guideline for positioning the distance of chambers for fire protection. The heat loads on it would be complicated to establish.

Current recommendations from the Department of Mines and Petroleum are that chambers must be within 750m of any underground personnel (1500m apart). Distances of this nature would likely produce conditions favourable for refuge chamber positioning.

Fire Rated Refuge Chamber Construction

MineARC has constructed several passive fire-rated refuge chambers, where insulation protects against fires of short duration and high intensity.

MineARC can provide a passive insulated chamber that is:

- Constructed of the same outer steel materials

- They are lined with insulation boards (DuraSystems, ASKIN or Bondor) to cover all external surfaces. These boards are installed to limit heat transfer occurring through the steel structure into the occupied volume.

- All gaps in the insulation are filled with a fire-rated sealant and caulk for protection. This insulation also limits the heat transfer into the occupied space.

- The insulation lined with steel cladding before it’s painted as per standard refuge chamber construction and materials

- The fire-rated caulk is also provided as a material within the chamber to protect against any unforeseen gaps.

- Fire-rated glands are used for all cable passes into the chamber.

- Plugs are available to block possible heat transfer. In extreme cases, heat may transfer through the check valves at the front of the chamber.

Insulation to Protect Refuge Chamber Components from Fire

A key consideration is heat removal from the chamber’s occupied space. A refuge chamber can become uninhabitable without an air conditioner to protect against latent heat and humidity.

It is essential to add insulation to protect the unit. If the exterior condenser of the air conditioner is exposed to extreme heat, causing it to fail.

MineARC’s current passive fire protection for refuge chambers includes insulated shielding at the rear of the shelter. The back houses the UPS cabinet; batteries are required to power the refuge chamber’s life support systems (scrubbing units, air conditioning and lighting), resulting in a loss of mains power.

The battery cabinet doors also include intumescent grill blocks that allow ventilation of the cabinet. These blocks expand to shut when exposed to elevated temperatures and a fire’s naked flame, forming an incombustible barrier to the spread of fire and hot smoke.

Refuge stations must include a portal window and a secondary means of egress (an escape hatch) to comply with all the current refuge chamber guidelines.

The passive protection solutions for these include a portal window cover and an external opening “kick out” escape hatch that can be caulk-filled and insulated. The internal occupied space of a passive fire-rated chamber is almost identical to a standard MineARC refuge chamber.

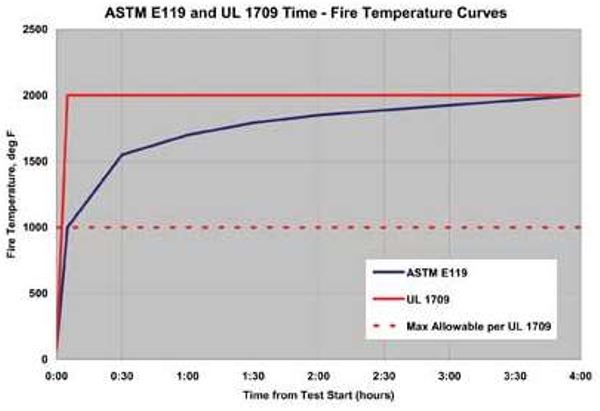

Time/Temperature Curves for Tunnelling

Fire Protection International Time/Temperature curves for Tunnelling Operations

MineARC has not yet been asked to provide a European tunnelling fire rated chamber compliant to any time/temperature curve. These curves map the temperature required to protect against throughout chamber use.

Tunnelling regulations base passive fire protection on hydrocarbon fuels that burn more intensely for shorter periods. However, the time would increase if a sizeable mobile truck were to ignite.

From the reviews done on the tunnelling standard for passive fire protection, the following time/temperature curve is used.

When reviewing the curve, it identifies that passive protection can be developed for the occupied space. However, current air conditioning systems, rated to an external temperature of 50 degrees, will need to be suspended for much of the fire duration. Therefore, alternative cooling would be required to meet the curve above.

Heat Suppression – Misting and Fire Extinguishing

MineARC also has misting systems that emit water vapour into the surrounding atmosphere. This water effectively reduces the ambient conditions and increases the ambient operating temperatures to as high as 60°C.

Fire suppression devices are fitted to chambers in areas likely to experience possible heat loading extinguished from the refuge.

Alternative Cooling Options in Tunnelling

Secondary cooling methods are a critical component to meeting any tunnelling time/temperature curve. This backup ensures there is an ability to continue to cool the occupied space during primary air conditioning suspension.

MineARC can provide a MARCiS liquid carbon dioxide (CO2) cooling as a secondary cooling method. However, CO2 bottles must be kept below 40 degrees and stored within an insulated chamber section.

The air conditioner cools this part of the chamber during its operation, and once the MARCiS is activated, the bottles cool the insulated room. The exhaust gas, CO2, is then plumbed to the battery cabinet and air conditioner bay to eliminate the oxygen and reduce fire spread risk.

This cooling method, however, is extensive and at times impractical. Thermal storage methods and continued research and development into secondary intrinsically safe cooling continue at MineARC.

Did you know? The exact level of protection from a potential threat such as a fire, the positioning of the refuge chambers, and the possible methods used to operate in higher ambient conditions are all factors continually developed at MineARC.