Compressed air is an integral part of underground mining and construction. It provides a source of power for operations including exploration drilling, refining and pneumatic tools as well as safe breathable air underground through ventilation systems and to refuge chambers.

What is Compressed Air?

Medical grade compressed air is a specialty gas that's filtered of breathing contaminants such as oil, excessive moisture, carbon monoxide, carbon dioxide and odours. Air is defined as the Earth’s natural atmosphere, is non-flammable and predominantly consists of nitrogen and oxygen.

The Importance of Compressed Air Supply to Refuge Chambers

Underground personnel need access to a safe location in the event of an irrespirable atmosphere cause by fire, toxic gas release or other hazards. If evacuation is not probable, refuge chambers provide respite from the exterior dangers. These complex environments use compressed air to help support life contained within.

The basic life-support features of a refuge chamber which rely on compressed air include:

- reliable and clean breathable air supplies

- the capability to seal personnel from an external irrespirable atmosphere

Breathable Air Supply to Refuge Chambers

Refuge chambers are designed to be used without warning; hence, they must always be emergency ready. This includes equipping chambers with a supply of breathable air that is ready for use at all times.

There are two sources of breathable air, which every refuge chamber is required to provide; a primary source of compressed air and a secondary source through the combination of oxygen cylinders and a chemical scrubber.

What is Breathable Air?

Breathable air is air that can support life, has enough oxygen in its mix, and doesn’t contain high levels of contaminants like carbon monoxide, carbon dioxide, water, or any other toxins that will poison refuge chamber occupants during entrapment.

A clean, safe supply of compressed air is delivered to refuge chambers via a dedicated line. This line must be free from oil and other impurities to prevent the contamination of the air within the chamber. Depending on the chamber manufacturer and regulations at its final location, the compressed air delivered must meet filtration specifications. For example within Australia and New Zealand, to provide a real source of breathable air, a refuge chamber’s filtration system must comply with AS/NZS 1716:2003, and clause 9.16 from the air supply standard AS/NZS 1715:2009 or their international equivalents.

Compressed air is noisy, and suppression measures can be added into the internal design of each refuge.

Using Compressed Air to Maintain Internal Positive Pressure

Overpressure inside a chamber prevents external toxins from entering. If airborne contaminants from the outer atmosphere enter the enclosed environment, they can compromise the quality of breathable air within the chamber.

The rate of compressed air flow should be set to maintain a slight positive pressure (200 Pascals) in the chamber, relative to the external atmosphere. Check valves control the positive pressure, which will open should the pressure inside the chamber exceed 250Pa. Excessive positive pressure will prevent the chamber door from opening, or risk damaging the chamber.

Compressed Air Filtration Systems vs. Compressed Air Management System

Compressed air supplied to refuge chambers needs to be of high respirable quality. As refuge chambers are confined environments, pumping in an unclean air supply can be detrimental to its occupants.

Compressed Air Filtration Systems

Compressed Air Filtration Systems are fixed to a refuge chamber to remove traces of contaminants such as water, carbon dioxide, carbon monoxide and other toxins. Most are equipped with a three or four-stage filtration process.

- Water Separation: Prevents large amounts of water entering the chamber.

- Preliminary Filter: Removes larger particles.

- Coalescing Filter: Removes finer particles of water or oil.

- Absorbent Filter: Removes diesel particulate, odours, volatile organic compounds, small levels of carbon monoxide and very fine oil particles.

Compressed Air Management System

MineARC’s Compressed Air Management System (CAMS) includes the four-stage filtration components as some CAFS options, with additional flood protection, overpressure avoidance, toxicity shut-off and monitoring features.

The design of the system reduces costs through airflow control and faster service time, whilst improving safety through refined air toxicity monitoring, an emergency shut-off valve and security against over-pressurisation.

Cost-Saving by Optimising Compressed Air Flow to Refuge Chambers

CAMS is designed to optimise the flow of air into the chamber to maintain positive pressure and remain emergency ready when unoccupied. The reduction in compressed air wastage is achieved through the inclusion of an air pressure sensor and shut off valve. These components allow for the improved regulation of airflow into the chamber; emitting periodic ‘bursts’ of compressed air to sustain positive pressure compared to a set flow rate.

Previously, refuge chambers were set to run at a continual 50% flow rate to maintain an operational standard. With the inclusion of CAMS, the need for a set flow rate is nullified.

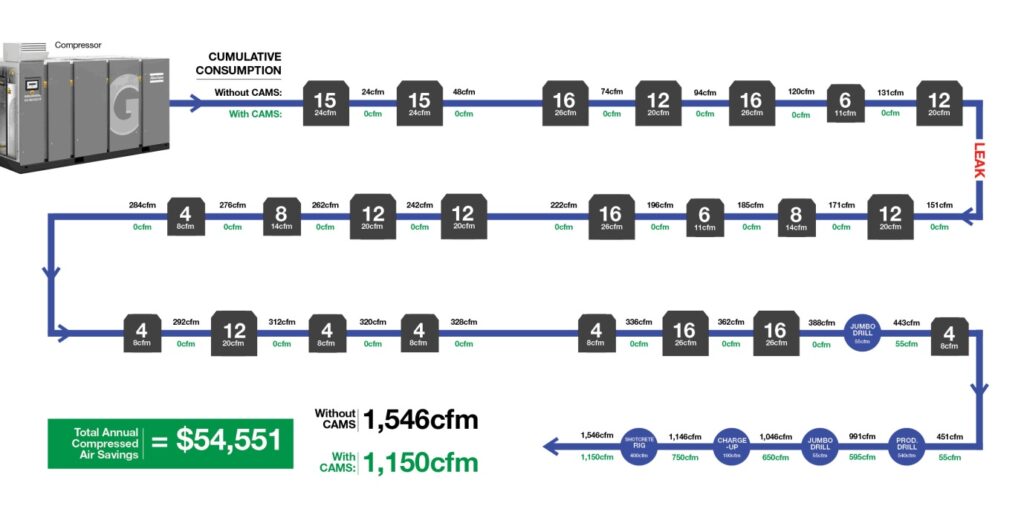

In 2017, MineARC Systems completed a comparative analysis of a mine site with and without a Compressed Air Management System. The review looked at the path a compressed airline would take from the surface to the sites major operational requirements; comparing a traditional 50% flow rate to the more modern CAMS method.

*Figures based on typical mine site operation. Compressed air flow to refuge chambers set at a conservative 50%. Leaks are hypothetical and could present more frequently. Order of production equipment will vary per mine site.

The analysis showed significant costs savings through the integration of CAMS onto a refuge chamber fleet.