Operating at a production capacity of 11 billion cubic meters per annum, PetroChina sought a proven safe-refuge solution for the gas refining plant servicing the area. In addition, they required a custom haven that could shelter workers in the event of a methane (CH4) or hydrogen sulphide (H2S) outbreak.

Essential requirements specified included:

- External surveillance

- Ability to withstand extreme temperature conditions

- Protection against potential explosions

- Gas monitoring

The custom 40-person ChemSAFE Safe Haven features a 12psi blast rating and a modular two-section design to allow easy transportation via shipping containers. In addition, fixed gas monitoring is installed both internally and externally, with the capability to monitor CH4, H2S, CO2, CO and O2 levels.

About PetroChina Oil and Gasfield

PetroChina Oil and Gasfield Southwest Company is a regional subsidiary of the state-owned China National Petroleum Company. PetroChina is the country’s largest gas producer, playing a dominant role in the global oil and gas industry.

In early 2014, PetroChina discovered a natural gas reserve big enough to supply China’s LPG energy requirements for almost two years. Located in Anyue County in Sichuan’s southeastern province, the reserve holds approximately 308 billion cubic meters of recoverable gas. The Anyue gas reservoir was the most significant gas discovery in China’s history, expected to strengthen China’s energy security and reduce reliance on imports.

In October of 2014, the Phase 1 capacity building project at the Moxi Block of the Anyue gas reservoir commenced, signalling the beginning of commercial development.

PetroChina selected MineARC as their manufacturing partner for the task due to MineARC’s strong reputation within the petrochemical industry. MineARC worked closely with PetroChina to engineer and manufacture a unique and technologically advanced solution that met all of their requirements.

Custom Features of the Chemical Safe Haven

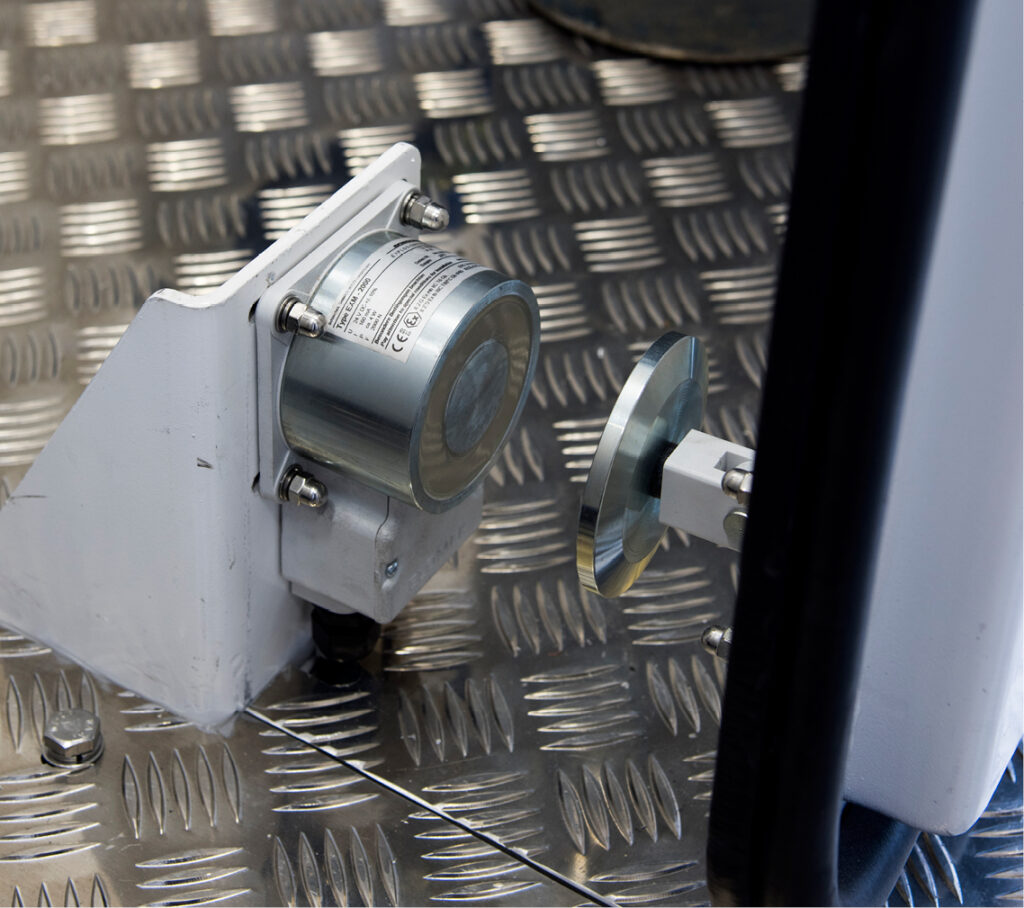

Camera Monitoring and Surveillance

The ChemSAFE chamber includes intrinsically safe external surveillance equipment, allowing occupants to review external conditions while within the shelter. A camera is mounted and raised with 360° degree horizontal and 90° vertical rotation to provide a superior vision.

A 23” high definition touchscreen within the main chamber allows occupants to control the external camera during entrapment. Also, all cameras can be monitored externally via the IP (Internet Protocol) remote network.

Auto Locking Vestibule Doors

The flushing vestibule features an automated door interlocking system linked to the safe haven’s external gas monitoring system. When conditions are safe, the system allows unrestricted access to the chamber. If unsafe gas levels are detected, the interlocking system will activate, only permitting access from the vestibule into the internal section once the exterior door is closed. This layer reduces the chance of contaminated air entering the main chamber.

Manual override switches allow qualified personnel to disengage this feature if required.

Safe Haven Digital Gas Monitoring

Internal and external gas monitors throughout the chemical safe haven report to a centralised control system within the main chamber.

A 15” high definition display panel provides occupants with an intuitive graphical dashboard of the system status and real-time gas level measurements.

Additional features of the chamber include:

- Series IV CO and CO2 scrubbing system with the capacity to also scrub CH4 and H2S

- i.V.A.N (Intelligent Voice Audio Navigation) system

- 4 hour UPS battery backup

- Thermal insulation and intrinsically safe air-conditioning to withstand temperatures of up to 50°C

- Private toilet facilities

- Mobile phone signal booster and charging

- Automated Oxygen Delivery System (AODS)

- Positive Pressure Flushing System (PPFS)

- Explosion rated intercom

The PetroChina ChemSAFE, custom safe haven, was recently commissioned at the gas refining plant of the Moxi block, Anyuegasreservoir in Sichuan Province, China. MineARC looks forward to working with PetroChina on more exciting projects in the future.