What is a Blast-Resistant Building (BRB)?

Definition: A Blast-Resistant Building (BRB) is a reinforced structure designed to reduce harm to personnel and equipment in the event of an accidental or deliberate explosion. BRBs are common within petrochemical plants, including manufacturing and chemical processing facilities, as well as oil refineries and defence sites.

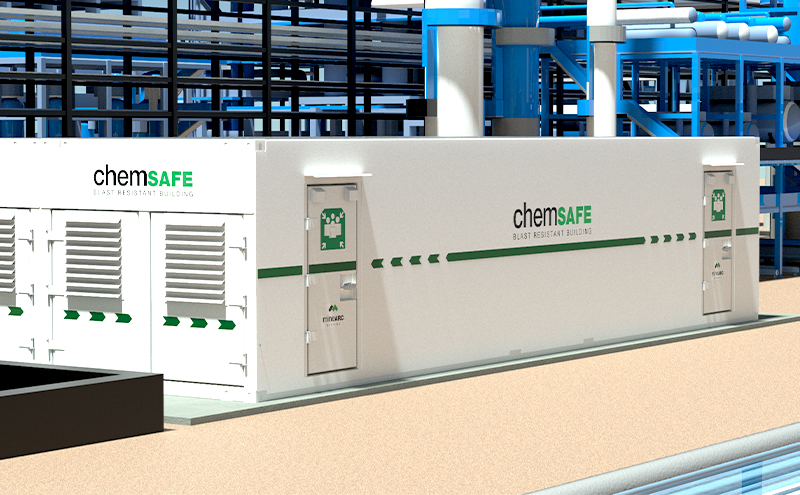

BRBs mitigate the effects of explosions, providing protection for humans, the structure, and the equipment inside. They can be permanent installations or portable blast-resistant modules. Whether fixed or transportable, BRB design must withstand or contain the forceful impacts caused by blasts and explosions, as well as resultant forces, including heat, noise and projectiles.

Why Would You Need a Blast-Resistant Building?

Explosions from ammunition or chemical reactions are unpredictable in nature; a crucial reason why blasts are considered so dangerous. In petrochemical and high-risk environments, explosions are a known threat, and preventative measures are put in place to reduce the risk of it occurring. Pre-emptive procedures do not guarantee an incident will not happen; therefore, additional safety measures need to be installed for such emergencies.

General building design does not factor in blast impacts. If an explosion occurs, a blast can produce an overload much greater than what the building was designed to withstand. This overpressure would cause severe damage to the building itself, its contents and significant adverse health effects or fatalities for occupants or people nearby.

Blast-related injuries are typically a result of three types of conditions:

- Primary impact resulting from the initial shock wave and blast overpressure

- Secondary effects from shrapnel and debris

- Tertiary injury related to impact on surfaces caused by movement

Blast injury associated with the different levels of impact, or hazards resulting from the explosion, can all have lethal implications.

Blast-Resistant Building Design Criteria

Before designing a Blast-Resistant Building in a petrochemical facility, you must identify and understand the potential dangers on-site and possibly surrounding areas. Understanding the risks first will help establish the extent of protection required to ensure the safety of personnel.

There are critical concerns to address when implementing blast response strategies. The initial blast which causes both positive and negative pressure waves impacting a building or shelter.

Also, how the shelter or building reacts once the blast diminishes, as an explosion causes extreme stress on the structural integrity of a building. While it may withstand the initial explosion, the added strain caused by continuous movement, weakened frames, and subsequent hazards such as fire and heat can cause a building to collapse.

Overall, the BRB design should consider:

- What strategies can mitigate risk, isolate the blast, and best types of engineering materials

- How the materials behave under excessive loading and blast overpressure

- Functionality and safety of the structure post-explosion

Blast resistant modules can provide practical alternatives to standard temporary building types for projects within proximity to hazardous materials. Portable BRBs are often constructed with heavy steel capable of withstanding blast pressure typically measured in pounds per square inch (psi) over a given impulse duration.

The Design of Blast-Resistant Buildings in Petrochemical Facilities

Blast Resistant Building Regulations and Guidelines

No global standard exists for blast-resistant structures. However, the American Petroleum Institute (API) provides recommended best practice for blast-resistant buildings, namely API 752 and API 753, and often used with guidance from the American Society of Civil Engineers (ASCE 41088);

- API 752 provides blast-resistant guidelines for permanent, occupied buildings

- API 753 provides blast-resistant guidelines for temporary and portable structures

The recommended practice aims to protect personnel in the petrochemical industry by outlining critical considerations for the design, construction, installation and maintenance of BRBs.