What is SMT or Surface Mount Technology? It is the process of mounting electronic components directly onto the surface of a Printed Circuit Board (PCB). This is an automatic manufacturing process, allowing electronic boards to be produced faster and more accurately than ever before.

What are the advantages of an SMT line?

SMT lines provide numerous advantages over traditional printed circuit board production methods. These include:

- Reduced manufacturing costs through a reduction in manual labour and material wastage

- Greater efficiencies with shortened production cycles

- Precision application in PCB manufacturing, resulting in higher quality PCBs

- Better safety practices through minimal manual handling

MineARC Australia has recently invested in our own in-house SMT Line. It is now in full operational mode within our electronics assembly room, which has been completely refurbished to include precise temperature and humidity control as well as antistatic vinyl flooring.

The assembly line can place over 20,000 SMT components per hour; utilising cameras to check electronic components prior to placement, and discarding any that are not to spec.

The chip components are stored on reels, which are barcoded and then installed into intelligent ‘feeders’. Components are then arranged in the most efficient configuration to minimise travel time; ultimately speeding up the production process.

Once a production run has been programmed by our MineARC SMT Operators, it can be reused over and over; minimising manual set-up time in the future.

What are the main elements of an SMT line?

SMT configurations will vary based on the application and the level of automation required. Generally speaking however, it will comprise of the following elements:

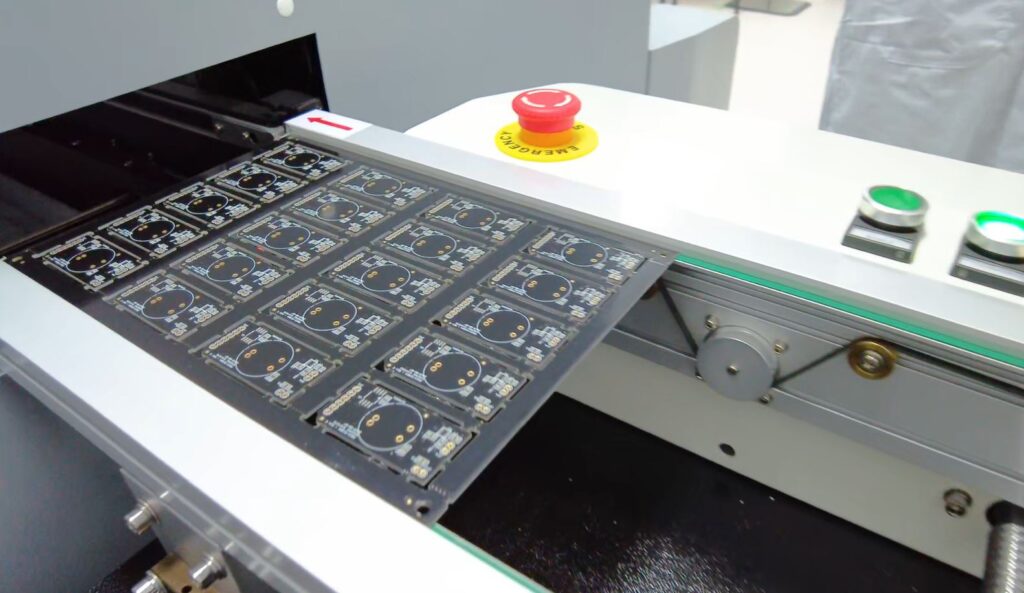

- SMT loader – automatically stacks and loads PCBs onto the conveyer

- Stencil printing machine – applies the solder paste to the blank PCBs

- Pick and place machine – accurately places the surface mount components onto the PCBs

- Oven – bakes the PCB boards using heat profiles best suited to the PCBA (Printed Circuit Board Assembly)

- SMT unloader – receives the completed PCBs on magazines after manufacture

The PCBs are automatically moved from one station to the next, with intermittent docking stations located throughout the process line to allow for manual inspection.

What is the typical SMT assembly process?

Beyond the physical configuration of an SMT line, what does the SMT assembly process actually look like? Simply put, it can be broken down into 8 steps:

1. PCB Preparation

The SMT process begins with the PCB being cleaned to remove any dirt or oil that could affect the soldering process.

2. Solder Paste Application

A thin layer of solder paste is applied to the PCB where components will be placed. This paste helps form the electrical connections during soldering.

3. Component Placement

SMT components are loaded into a pick-and-place machine that will automatically pick up small components like resistors, capacitors, and chips, and places them in the right spots on the PCB. Component placement is determined by design data to ensure proper positioning.

4. Reflow Soldering

The board is heated in a reflow oven, where the solder paste melts and forms solder joints, securing the smaller components onto the PCB.

5. Inspection

After the molten solder has cooled and solidified, automated optical inspection (AOI) is used to check for defects such in the PCB assembly process such as missing or misaligned components, or solder bridges (short circuits). In some cases, X-ray inspection can be used to check the quality of a solder joint if there are components with hidden or fine-pitch leads.

6. Testing

The board undergoes tests, such as in-circuit or functional testing, to ensure it works correctly. Any issues are fixed.

7. Cleaning

The PCB may be cleaned to remove leftover flux or paste.

8. Final Inspection

A final check is done to ensure everything looks good, then the boards are packed for shipment or further assembly.

Why does MineARC need an SMT line?

As MineARC Systems’ range of smaller electronic products continues to grow and advance, our need for complex printed circuit board production only continues to increase. Bringing this process in-house gives us full control over the quality, quantity and timeframe of our printed circuit board production; whilst allowing us to expand and accelerate our R&D capabilities in this area.

Listen to Daragh Quinn, MineARC Australia’s Engineering Manager speak more about our newest manufacturing capability in the video below.