Pioneering the Lyon-Turin Rail Project, a modern transport line connecting France and Italy is TELT (Tunnel Euralpin Lyon Turin). Here they share some insight into how the tunnelling project is progressing, its infrastructure, and how they set out to achieve their safety goals.

TELT and the Lyon-Turin Rail Project.

TELT is a French company founded in 2015. It is the binational public promoter responsible for the construction and management of the cross-border section of the Lyon-Turin mixed freight and passenger railway line. The cross-border area extends over a stretch of 65 km.

The main element of the project is the 57.5 km long Mont Cenis base tunnel, 12.5 km in Italy and 45 km in France. This tunnel links the international stations of Saint-Jean-de-Maurienne and Susa, which are the connection points to the railway lines in France and Italy.

The project is part of the TEN-T (Trans-European Transport) Network which extends for 3,000 km, connecting seven European Union (EU) corridors from East to West. It represents the central link of the Mediterranean Corridor. For this reason, it is co-financed by the EU (within the actions supporting the European green deal strategy), Italy, and France.

What stage of the tunnel project are you? How much further do you have to go?

The history of the project began in the ’90s, involving several governments and local communities. In 2015, the project was confirmed by the two States in agreement with the European Union.

To date, the first 30 km of tunnels out of 162 km, have been excavated, including ten of the south tube of the base tunnel, declines, and interconnection links. The line is scheduled to become operational in 2030.

What has been your most significant milestone so far?

Some of the key achievements so far, include:

- The completion of the four declines, which took place between 2007 and 2017.

- In 2019, the first 9 km of the base tunnel’s south tube was excavated. In September 2020, the excavation of a further one and a half kilometres using conventional method has reached one kilometre.

- In 2021, the entrance portal to the base tunnel (cut-and-cover tunnel) on the French side, and the interchange niches inside the La Maddalena tunnel on the Italian side, will be completed.

- Furthermore, 21% of the contracts necessary for the realisation of the project have been awarded.

How many people are working on the project?

Currently, about 700 people work on construction sites and engineering companies in the two countries.

During the peak of activities, starting in 2024, there will be up to 8,000 workers directly hired or employed in the related industries, through 20,000 contracts.

What type of TBM is used across the tunnel project? Why was this type chosen?

Until today two Tunnel Boring Machines (TBMs) have been used: Gea in Italy for the excavation of La Maddalena exploratory tunnel and Federica in France for the excavation of the base tunnel.

In the case of Gea, the excavation goal was to understand the possibility of mechanised excavation in points that could have more than 1000 m of rocks. The aim for Federica was to excavate the tunnel where the trains will pass, assembling the lining segments at the same time.

The first was an open-type TBM, with a diameter of about 6 m, produced by Robbins. In contrast, the second is a shielded TBM, with a diameter of 12 m, was built by NFM.

Together with the TBMs, pneumatic hammers and explosives were used for smaller and more delicate sections.

BIM (Building Information Modelling) technology is used on the project; how does this help you manage construction and safety?

The 57.5 km twin-tube tunnel under the Alps, aims to improve the long-term logistics and mobility between Italy and France. Therefore, it’s construction requires innovations capable of controlling works during and after its development.

In this context, the integration and updating of information (architectural, structural and plant design, characteristics and properties of materials, components and systems, planning of construction phases, timing and execution costs, maintenance works) through BIM technology monitors the overall project, helping to speed up the construction process, reduce costs, increase reliability, and minimising errors or risks.

Moreover, BIM allows us to keep track of all transformations and adjustments needed over time.

In your goal to minimising accidents in the workplace and create a healthy environment, you have created a dedicated corporate function. Can you tell us about this, and how safety has improved/ changed on the project?

Since the birth of TELT, the Directorate General imposed the mandatory goal, “Zero Deaths and Accidents”. For this reason, professional profiles provided for by Italian and French regulations, have been hired to ensure compliance with the standards and the health of workers inside and outside the construction sites.

In 2020, TELT chose to create a new corporate department called Sustainable Development and Safety. This department combines the Environment and Safety functions with a specific strategic approach, based on research, innovation, as well as the EU 2030 Agenda goals and the Green Deal.

TELT faces the challenge of safety in the workplace, as well as rail safety for service users, and actively aims to become an example in the prevention and protection of life and health.

You have a MineARC TunnelSAFE Refuge Chamber on the TBM, what safety benefits do refuge chambers bring to the project?

“The most important thing to come out from a mine is the miner”. This motto, taken from the mining industry, reminds us that the project and the organisation of underground work must always deal with the effectiveness of emergency systems.

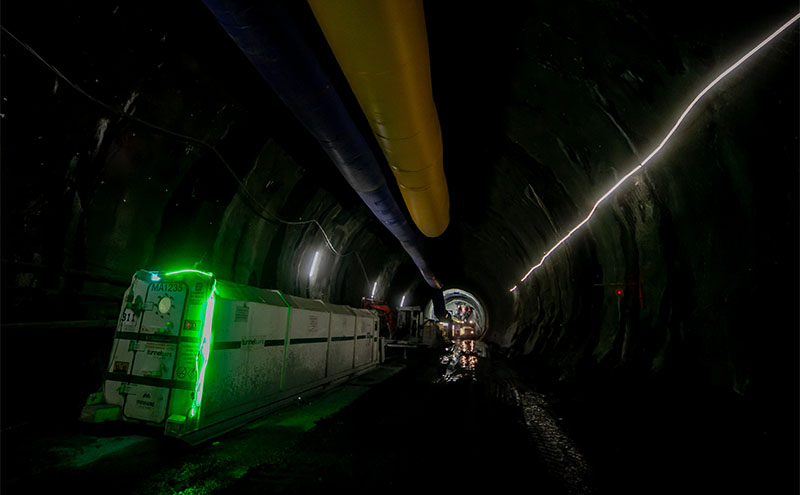

Tunnel excavation is often carried out for long stretches on a single excavation front, and the only way in is also the way out. It is also the same path from which the air to breathe, energy, water, and communication with the outside arrives.

If this way became obstructed, people find themselves trapped, with serious risks to their survival. Therefore, it is necessary to have safe places available to wait until safety conditions are re-established, and the rescue team arrives.

The on-site refuge chambers are located within walking distance (even with the use of personal protective equipment) and are no more than 500m apart. In these chambers, people can find air, light, water, shelter from fumes, and emergency communications to signal their presence to the rescue team.

Tunnelling refuge chambers can also accommodate a few dozen trained people with an autonomy of at least 24 hours; therefore, rescue vehicles have enough time to reach them.

The construction site of SMP4 represents a typical example of the use of these chambers, which are essential in tunnel construction nowadays.