Engineering a refuge chamber for tunnels under construction requires a technical review of the industries challenges. A tunnelling emergency differs from resources-based underground environments. Hence these shelters need to meet the specific dangers of the industry and the conditions of each project.

Building a refuge chamber for a tunnel proposed many challenges, including; maintaining a respirable atmosphere and regulating temperature and humidity.

When designing the TunnelSAFE, a tunnel specific refuge chamber, MineARC’s engineers refined and adapted the specialised life support components to overcome a tunnel’s confined conditions.

Why Do Tunnels Under Construction Need a Refuge Chamber?

Tunnelling Refuge Chambers are sealed steel containers with an artificially controlled atmosphere. The shelters maintain a habitable environment to support life during an underground tunnelling emergency.

The principles of life support focus on controlling the following:

- Positive Internal Environment: A secure sealed internal volume is positively pressurised to ensure contaminants are unable to enter the occupied space

- Breathable Air: Respirable air with multiple redundancies; required within a closed-circuit breathing apparatus that is the refuge chamber

- Habitable Environment: Temperature and humidity control

- Power: Electrical redundancy, with the use of a 24-hour uninterruptable power supply, to operate scrubbing equipment, air conditioners, lighting and gas monitoring equipment

The methods to achieve these conditions compare to those found in submerged submarines and have been around for some time. However, designing a tunnelling refuge chamber possesses several unique challenges that require specialised features in all key areas.

Design Requirements for a Tunnelling Refuge Chamber

Challenge: How to Maintain a Respirable Atmosphere in a Tunnelling Refuge Chamber

Externally compressed air is usually the primary source for respirable air within a TunnelSAFE Refuge Chamber.

To ensure adequate breathable air within an underground shelter, MineARC Systems explored the

- operational patterns of underground compressors as a primary breathing air supply;

- the risks posed by the potential supply of polluted compressed air both during occupied and non-occupied scenarios;

- and methods to remotely monitor and control the contaminated air from entering the sealed space.

Underground fires are one of the primary breathing contaminant sources and reasons to evacuate to a refuge chamber. Therefore considerations around compressed, oxygen-deprived, increasing carbon monoxide levels and high-temperature air, were used to begin design work for this life support system.

Solution: Compressed Air Management System (CAMS)

A feature of MineARC’s tunnel refuge chamber design (TunnelSAFE) is the Compressed Air Management System (CAMS). The part is designed explicitly around the challenge of maintaining a respirable atmosphere within an enclosed space.

An oxygen sensor is used to monitor incoming compressed air and will de-energise a customarily closed solenoid in the event of low oxygen. Air sourced from an area experiencing a fire or an environment likely to contain carbon monoxide due to incomplete combustion will also have reduced oxygen levels. This system allows the internal volume of a refuge chamber to remain respirable with or without occupants.

Positive Pressure Prevents Air Contamination

Refuge chambers require a positively pressurised internal volume to prevent breathing contaminants’ ingress. Positive pressure is reached by continuously bleeding the same breathable compressed air source into the shelter during standby mode.

A differential pressure controller is used to introduce compressed air only when required, preventing excess compressed air wastage and reducing the compressors’ demand to supply them.

Challenge: Temperature and Humidity Control in Sealed Environments

In tunnelling applications, the effect of high ambient conditions for conventional air conditioning units is often considered.

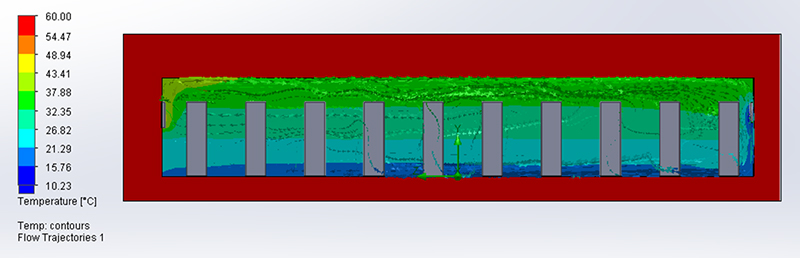

Most common air conditioning heat exchangers cannot reject heat higher than an ambient temperature of 47°C. ‘High temperature’ air conditioners are often rated to 60°C but will have a more significant power draw and lower adequate cooling capacity.

Solution: Computational Fluid Dynamics (CFD)

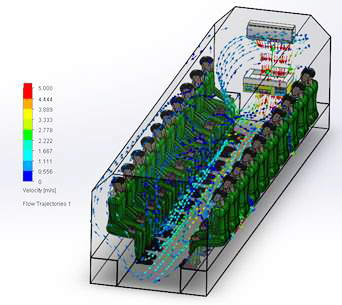

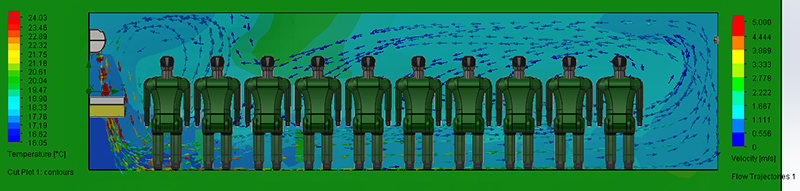

MineARC has existing high temperature and insulated designs that incorporate Computational Fluid Dynamics (CFD) modelling and analysis to ensure occupant safety. CFD simulates fluid flows and heat transfer, analysing the characteristics with numerical methods.

Furthermore, MineARC can employ MARCiS (Liquid Carbon Dioxide) and thermal storage cooling methods within atmospheres as high as 300°C.

Computational Fluid Dynamics Examples

Firstly, establishing a baseline identifies if air conditioning or insulation is required. Metabolic heat output is quantified as 117W, though 130W is used in these conditions.

Figure 1.0 shows that the chamber is already reaching uninhabitable environmental conditions within the first 30 minutes of entrapment. If the shelter detailed in Figure 1.0 reached saturation, the heat index would exceed survivable limits within 30 minutes.

Figure 2.0 and Figure 3.0: Computed with our standard operating conditions, show the significant mixing ability by drawing in contaminated air through chemical scrubbing cartridges.

Although this scenario does not consider the high ambient temperatures, it does add weight to the mixing and cooling ability of a standard chamber in high-temperature conditions.