Petrochemical and Chemical Processing Safety Solutions

MineARC is contractor management certified with Browz, Avetta and ISNetworld, which connects qualified contractors, organisations and suppliers with expert solutions.

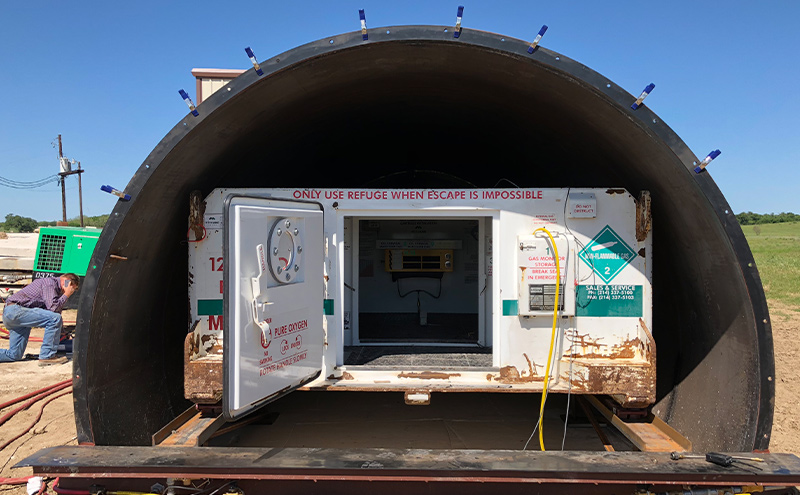

Transportable ChemSAFE Safe Havens

ChemSAFE Safe Havens provide a unique and cost-effective alternative to shelter-in-place; allowing flexibility as site requirements shift over time. Our Safe Havens are meticulously engineered to ensure complete protection from the outside environment, including a robust shell with up to 12psi blast rating, a fully pressurised vestibule, and 0% ACH (External Air Change per Hour).

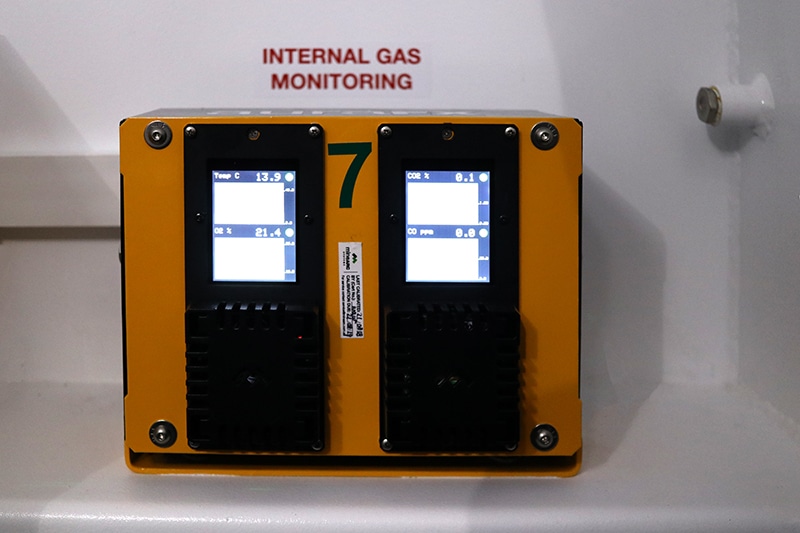

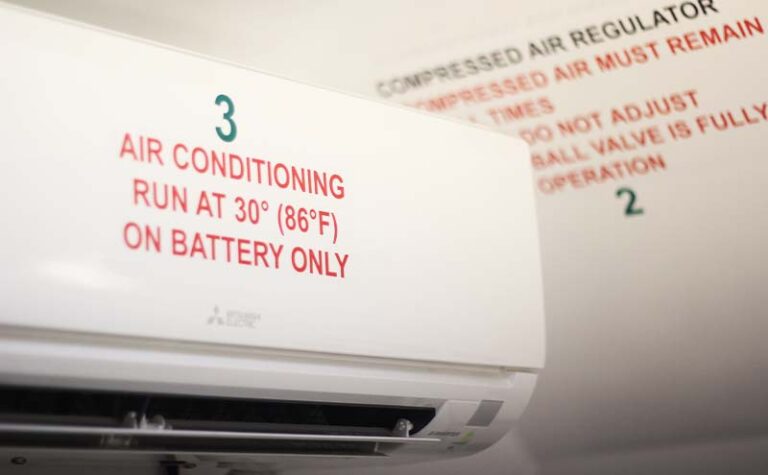

The ChemSAFE Safe Haven boasts a range of unique life-support features that have been engineered specifically for sustaining life in a sealed room. Systems include; a proprietary CO2 ‘scrubbing’ system with digital control and voice prompts, breathable oxygen supply, air conditioning, an advanced digital gas monitoring system, and UPS battery backup.

Industry Impact

GuardIAN Intelligence Network

Air Quality Management

Air quality management products by MineARC Systems are designed to create safe, breathable air for personnel sheltering in an enclosed space, away from toxic chemicals.

During entrapment, carbon dioxide is expired by the occupants as part of their normal breathing activity. Carbon monoxide and other toxic gases can also enter the main chamber via the compressed air intake (if it becomes compromised), and as occupants enter and/or exit the main chamber entrance.

Integrity Testing

Integrity testing can identify leaks within a room before converting the area into a Shelter-in-Place (SIP) or sealed room. Buildings are typically constructed to provide natural or forced ventilation to allow permanent occupancy. Structural room features such as large exposed windows and surfaces present challenges for ensuring protection during a blast event and the danger of subsequent chemical release.

MineARC Systems have the testing ability in-house that allows us to establish baseline integrity readings and provide a greater indication of your current level of protection against ingress.

Our integrity testing system is engineered to be portable and able to travel to individual sites for verification and auditing purposes and is ideal for generating an accurate baseline position for risk assessment.

Pressure and Blast Testing

In highly explosive environments, MineARC’s industrial emergency protection shelters can be adapted to withstand specific overpressure measured in psi (pounds per square inch). A safe havens resistance to explosions can be determined through pressure testing.

MineARC has the engineering capabilities to perform in-house blast analysis calculations on all refuge chambers and safe havens. Also, third-party testing can be executed by professional structural engineers.

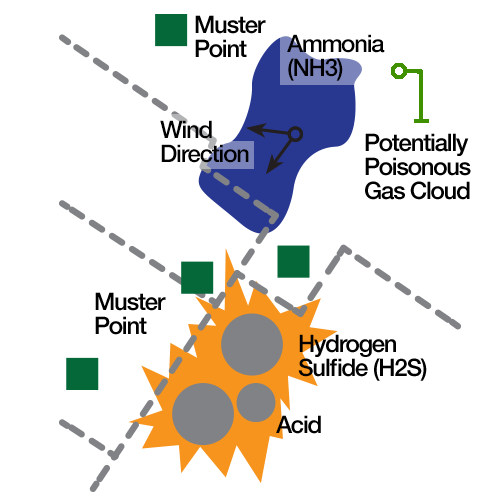

Emergency Action: Shelter vs Evacuation

Two protective actions commonly used in the event of a blast or chemical release are evacuation or seeking refuge in a shelter-in-place or safe haven. Time, size of the hazard, and location are just a few variables that can impact your ability to evacuate safely. When evacuation is not possible, these shelters provide a safe alternative and are an essential part of emergency management.

Implementing prevention, response, and rescue measures are imperative in dangerous environments. However, there are several factors which can influence the effectiveness of emergency action and instructions;

- An incomplete understanding of the root cause of fires, explosions or gas releases

- Deficiency in practical engineering controls to prevent, detect, and mitigate disasters

- Inadequate training of personnel, about methods to predict, prevent, and deal with a chemical emergency

- Combining emergency response plans for fire with chemical releases

Installing protective rooms shelters such as safe havens, blast-resistant buildings, and Shelter in Place (SIP), is a mitigation control to reduce the loss of life, and damage to property, equipment and supplies when preventative controls fail. When it comes down to it, these shelters help to improve survivability.

Frequently Asked Questions

Shelter in Place (SIP) is a common term used in community and commercial emergency response action plans. It refers to the process of taking refuge when you hear instructions to act immediately by staying indoors and sealing your environment until authorities provide additional instructions to leave the shelter when the rest of the area is safe. Read More about Shelter in Place

A Blast-Resistant Building (BRB) is a reinforced structure designed to reduce harm to personnel and equipment in the event of an accidental or deliberate explosion. BRBs are common within petrochemical plants, including manufacturing and chemical processing. Read More about Blast Resistant Buildings.

A safe haven or refuge chamber is a sealed room or environment, in which you can take shelter during a hazardous event when evacuation is not possible. Read More about Refuge Chambers.

Removing personnel through evacuation is not always possible. A multitude of factors, including the lack of adequate pre-warning, will significantly impact the emergency action undertaken. As a primary means of protection, have a shelter in place is the most survivable option when evacuation is not possible. Read More.

Working in the petrochemical industry can be dangerous given the nature and associated risks of the toxic chemicals and related manufacturing equipment. It is crucial that organisations prepare and protect their employees’ health in case they are faced with dangerous hazards. Hazards can include flammable spill from handling petrochemicals, technical faults, equipment malfunction, human error or process failures such as mental fatigue.

Depending on where your petrochemical plant is operating, there will be local safety and compliance standards to follow and maintain. Standard hazardous material procedures will depend on local health departments and the local officials.

By identifying unsafe work procedures and having key strategies in place, including easy access to surrounding safety equipment, the impact of dangerous, emergency situations can be minimised. With the necessary knowledge employees will know to act quickly by immediately taking themselves to a designated safe location and remaining inside the sealed room for further instructions.

Investing in a safe haven, shelter-in-place or sealed room is just one of ways that your site can prepare for risk and protect employees in a life or death emergency situation.

Interested in finding out more or need advice on MineARC’s ChemSAFE petrochemical and chemical safety shelters? Get contact and speak with the team by enquiring today.

Latest News

Ammonia: Health and Safety Hazards Fact Sheet

Ammonia hazards can occur during manufacture, use, and transportation. Knowing the health and safety hazards of anhydrous ammonia are vital to ERPs.

Pressure Testing A Refuge Chamber For Explosions

In highly explosive environments, refuge chambers and safe havens can be adapted to withstand overpressure of up to 15 psi. A refuge chambers resistance to explosions can be determined through pressure testing.

Controlling Temperature in a Refuge Chamber

Controlling the internal temperature of a refuge chamber is critical to the health and well-being of trapped miners and personnel