Chamber Refurbishments and Upgrades

Bring new life to your current chamber fleet.

The MineARC Refuge Chamber Refurbishment and Upgrade Programs transform damaged, worn or second-hand chambers into fully functioning, certified refuge chambers that look as good as new.

The program is available to MineARC and non-MineARC Refuge Chambers alike; bringing new technology and the latest life-sustaining systems to your collective fleet.

Refuge Chamber Refurbishments

The MineARC Refuge Chamber Refurbishment Program transforms older, used chambers, to a newer, fit for purpose model. Ensuring it meets the safety standards of the organisation is a significant consideration, as are government guidelines and MineARC Systems quality assurance.

What makes refurbishments different from chamber upgrades is the extensive overhaul and remodelling. The program involves a number of vital stages, including fabrication, painting as well as componentry repair and replacement, in order to bring a refuge chamber back into certification and optimal working condition.

Every refurbishment is different and quoted based on factors such as:

- Extent of damage or wear to the chamber

- Age of the chamber

- Make of refuge chamber

All refurbishments are conducted at one of MineARC’s state of the art manufacturing facilities by qualified workshop technicians. Following a refurbishment, one of our service technicians will conduct a comprehensive 50-Point Safety Audit, ensuring the chamber is commissioned, certified and meets MineARC’s stringent safety standards. This will give you peace of mind and the reassurance that your chamber is covered by our AU$20 Million product liability insurance.

For more information on how we can help refurbish your refuge chamber, contact MineARC now.

- Ensure your refuge chamber fleet is re-certified and complies with MineARC Standards

- Dramatically reduce refuge chamber operating and maintenance costs

- Receive a full service and 50-Point Safety Audit, conducted by a qualified MineARC technician

- Receive regular product support and access to readily available spare parts

- Enjoy peace of mind that your Refuge Chamber fleet is operating optimally in case of an emergency

The first stage of a refuge chamber refurbishment is the fabrication of any sections of the chamber shell that have incurred structural damage due to negligence, accident or general wear and tear from years of sitting underground.

Our engineers and experienced workshop technicians will perform a comprehensive assessment of the state of the refuge chamber structure and condition of the skids, battery box and doors in order to ascertain what requires full re-fabrication or repair.

After any necessary fabrication work has taken place, the outer shell of the refuge chamber is sandblasted and repainted. MineARC utilises a special high durability white paint for all of our refuge chambers. This aids in underground visibility, provides protection against corrosion, and complies with AS/NZS 2312:2002.

Painting is performed by a qualified spray painter to ensure a quality finish and long life in any harsh industrial environment.

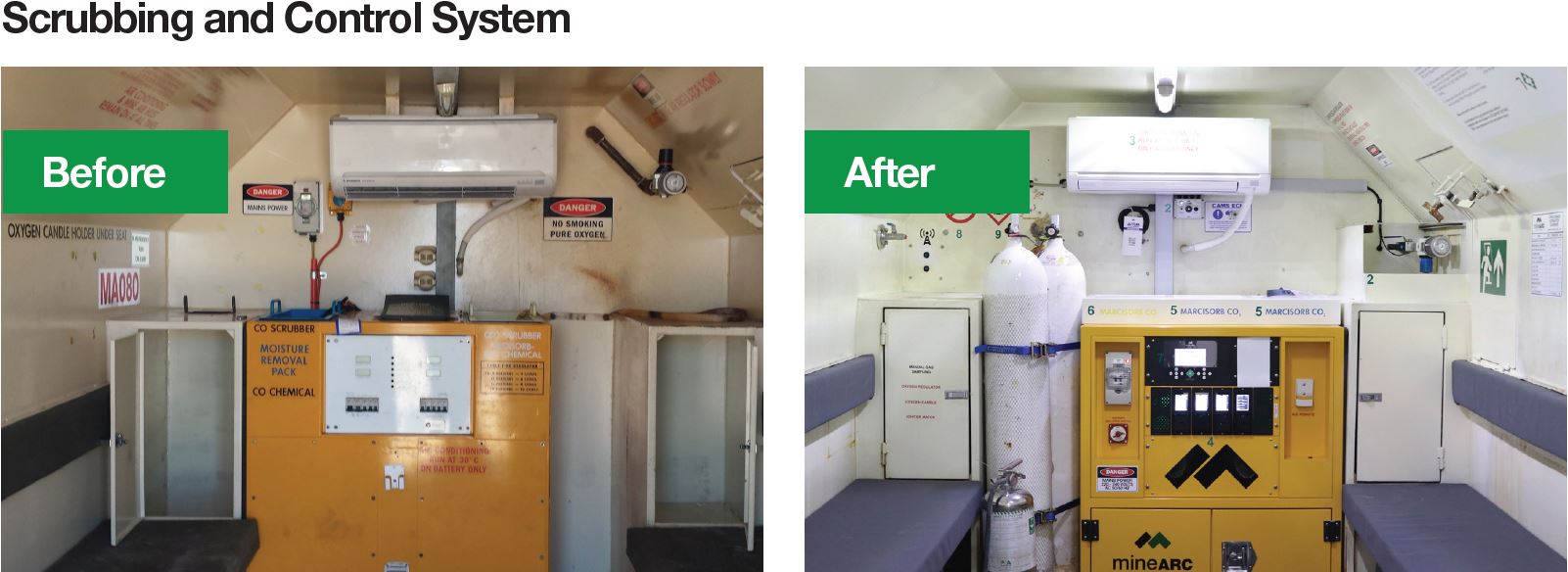

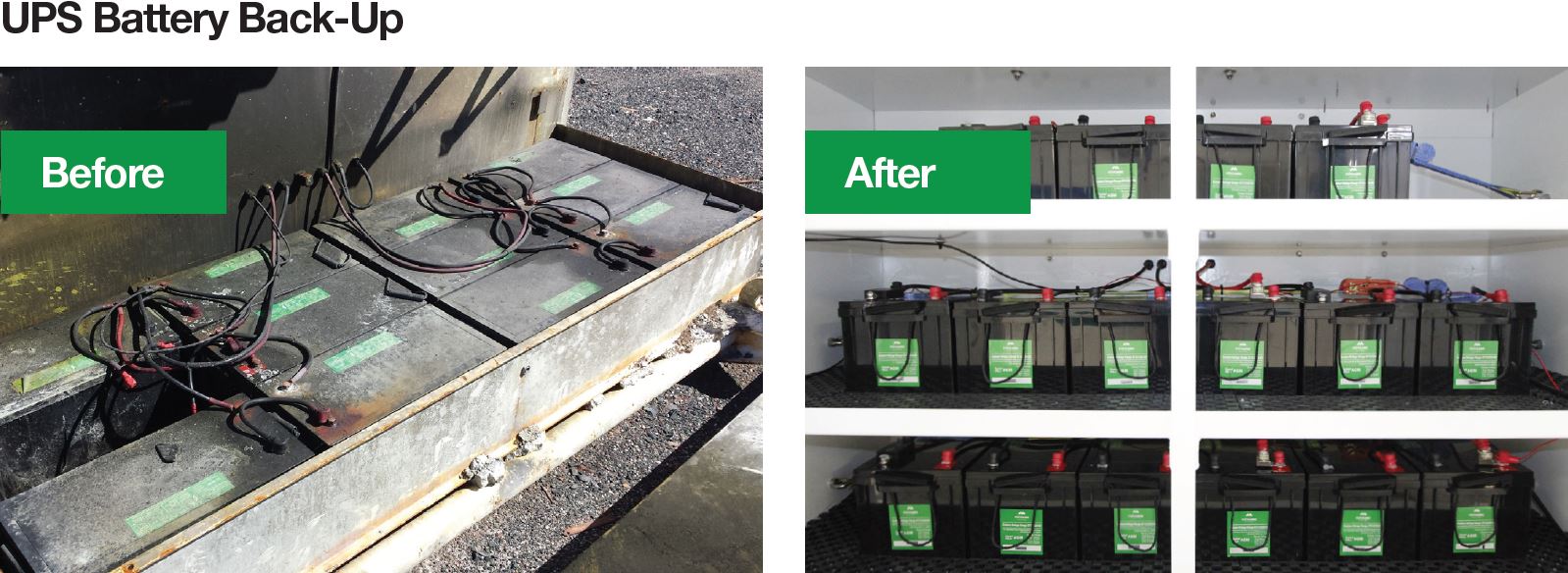

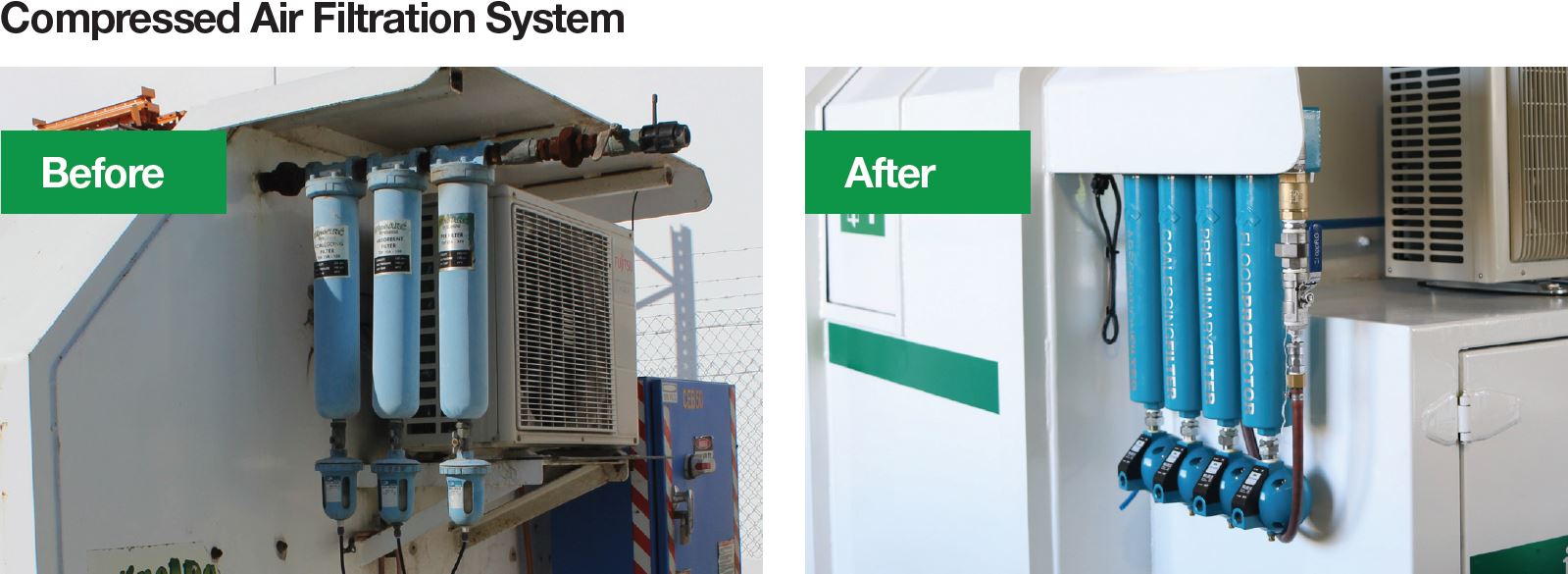

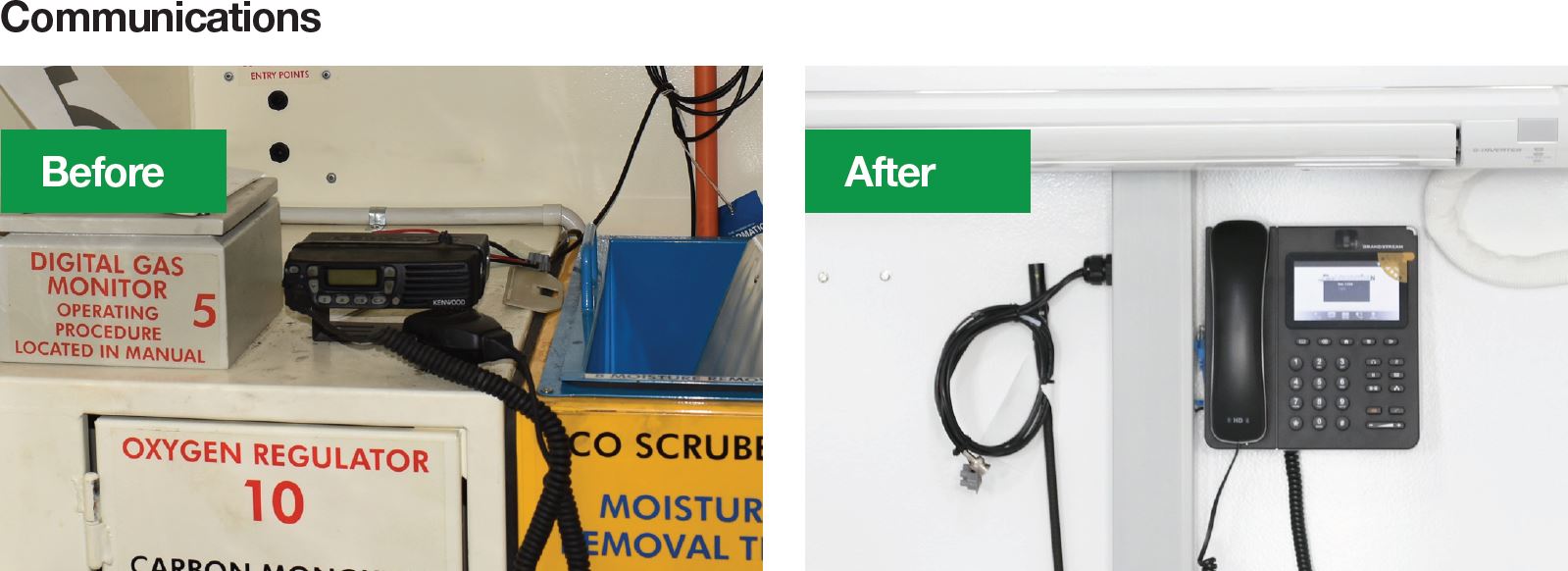

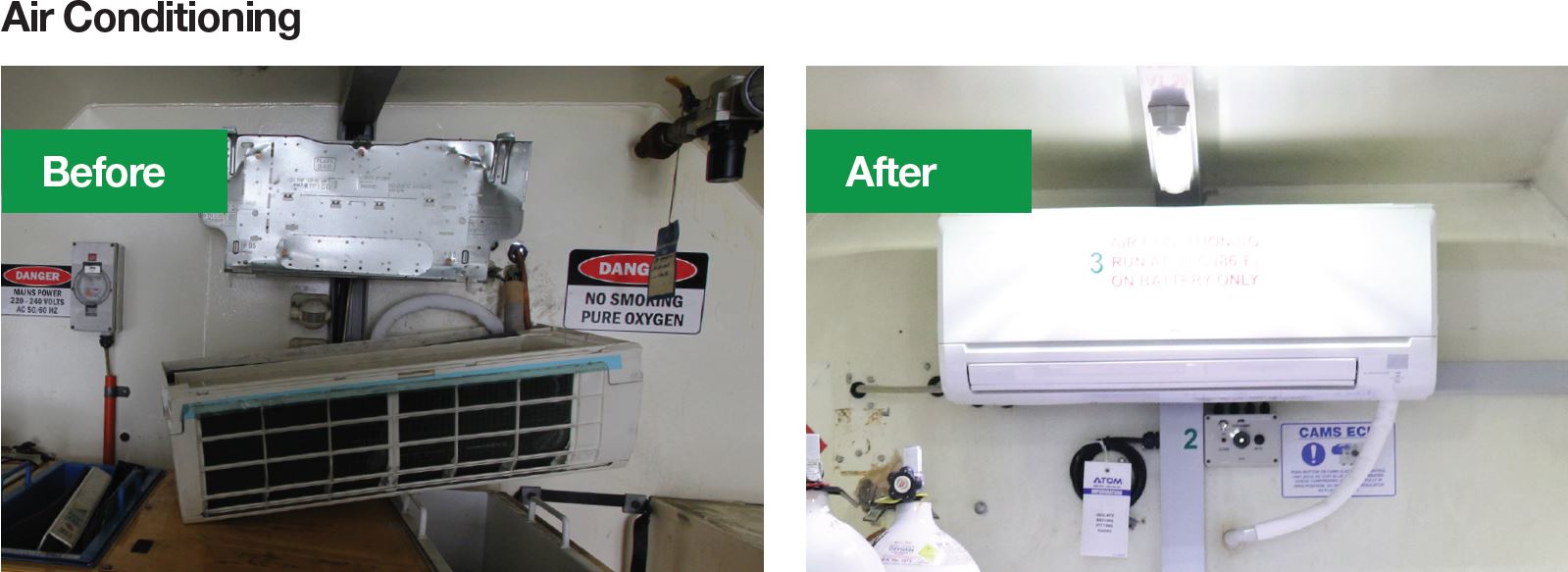

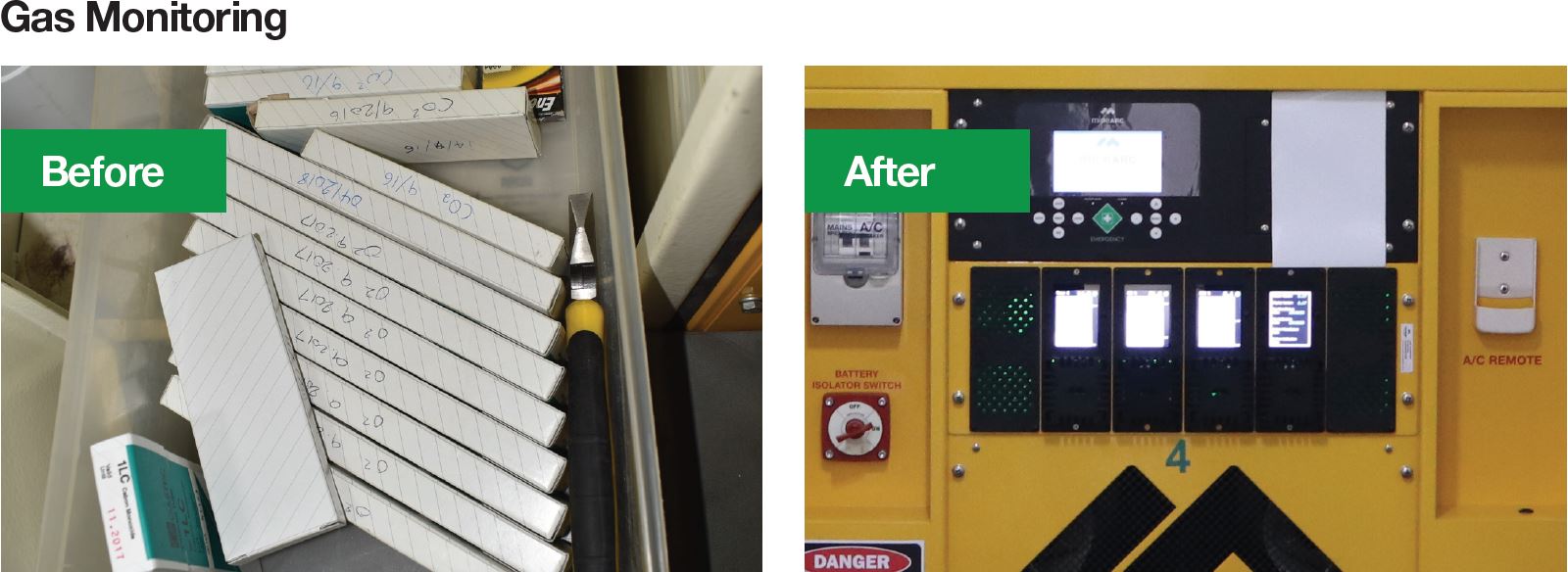

After the shell of the refuge chamber has been repaired and the exterior repainted, all internal and external componentry is inspected and tested for damage and general wear and tear. Parts will be repaired or replaced based on the extent of damage to ensure the chamber is in full working condition once again.

Operational and performance checks include:

- Scrubbing and control system

- Compressed air filtration system

- Secondary oxygen supplies

- Air conditioning and dehumidifying

- Check valves

- Door and escape hatch seals (including vacuum test)

- UPS battery back up

- Strobe lighting and siren

- Internal lighting and communications

- Toilet, first aid kit, food and water

Following a refurbishment, one of our service technicians will conduct a comprehensive 50-Point Safety Audit, ensuring the chamber is commissioned, certified and meets MineARC’s stringent safety standards. This will give you peace of mind and the reassurance that your chamber is covered by our AU$20 Million product liability insurance.

Operational and performance checks include:

- Scrubbing and control system

- Compressed air filtration system

- Secondary oxygen supplies

- Air conditioning and dehumidifying

- Check valves

- Door and escape hatch seals (including vacuum test)

- UPS battery back up

- Strobe lighting and siren

- Internal lighting and communications

- Toilet, first aid kit, food and water

Refuge Chamber Upgrades

MineARC’s key priority is to offer the most advanced and innovative safe refuge solutions on the market. Our success in the industry is achieved by listening closely to our clients’ requirements; allowing us to continue to develop products that are safer, more user-friendly and more cost-effective.

The MineARC Client Upgrade Assist Program offers a range of upgrade options that will improve the operation and efficiency of your chamber, both during an emergency and while in standby mode.

All upgrades are conducted on-site, and in most cases do not require chamber repositioning. Our qualified service technicians will conduct a comprehensive chamber audit and certification following the upgrade, ensuring the chamber is officially recertified to meet industry standards.

All upgrades can be conducted on-site, and in most cases do not require chamber repositioning. Also available are refurbishment options which require off-site repairs, including fabrication, sandblasting and painting, and general componentry replacement.

Other MineARC Client Support

Contact our friendly support centre seven days a week for troubleshooting assistance, on-site induction opportunities and chamber commissioning.

Free training courses, providing clients the opportunity to upskill in areas such as service, electrical and the general operation of our chambers.

Regularly servicing and performing maintenance checks on a refuge chamber will help ensure your equipment is ready in the event of an emergency.

Transform damaged, second hand chambers into a new fleet that is certified and fully functioning. Available for MineARC and non-MineARC chambers.

MineARC’s in-house engineering & innovation team are on hand to provide customised design solutions and explore collaboration opportunities.