Petrochemical Shelters for Hazardous Environments

- ChemSAFE Safe Havens

Petrochemical shelters from MineARC’s ChemSAFE range offer a safe and secure go-to area for multiple personnel in the event of a toxic chemical release, fire, explosion or other hazardous emergency response scenarios. The range includes fully transportable Safe Havens and Toxic Gas Shelters as well as Shelter-in-Place Room Conversions and Sealed Rooms with purpose-built life support systems.

Portable Safe Haven

- ChemSAFE Standard Design

The ChemSAFE Standard Design Safe Haven has been continuously refined to offer the latest in safe refuge technology, providing chemical facility occupants with optimal protective features such as blast resistance, toxic gas protection, scrubbing, and remote monitoring.

- Blast & toxic gas protection

- Zero air changes per hour

- Advanced Series IV Control System

- 8-40 people

Toxic Gas Shelter

- ChemSAFE Utility Design

The ChemSAFE Utility Design Toxic Gas Shelter is engineered for chemical protection; featuring a narrow construction for space restricted applications. The shelter’s ultra-portable design features lifting lugs and forklift slots, allowing easy manoeuvrability around any facility.

- Toxic gas protection

- ELV Control System

- Narrow shell for space restricted areas

- 6-30 people

Blast Resistant Building

- ChemSAFE BRB

MineARC’s ChemSAFE Blast Resistant Buildings (BRBs) are designed to provide protection from an industrial hazard such as a blast or flammable gas release. The open space pre-fabricated steel buildings can serve as work spaces or break rooms for general day-to-day use.

- Multi-use building design

- Up to 10psi blast rating

- Integrated life support options

- Network connection, smoke detectors

Shelter-in-Place

- ChemSAFE Custom Projects

ChemSAFE conversion of an existing room to Safe Haven allows occupants to shelter inside buildings, providing high levels of protection from toxic release.

- Customised modular construction

- ACH<0.1

- Integrated life support options

- Electrical packages available

- Custom capacities

What is a Petrochemical Shelter?

| Model | Rating (psi) | Height (m/ft) | Width (m/ft) | Length (m/ft) | Weight (kg/lb) |

| PS-BR-9-12-12-1P | 1 | 2.75 / 9 | 3.65 / 12 | 3.65 / 12 | 6300 / 13700 |

| PS-BR-9-8-20-1P | 1 | 2.75 / 9 | 2.44 / 8 | 6.10 / 20 | 6000 / 13100 |

| PS-BR-9-12-40-1P | 1 | 2.75 / 9 | 3.65 / 12 | 12.20 / 40 | 13300 / 29200 |

| PS-BR-9-20-40-1P | 1 | 2.75 / 9 | 6.10 / 20 | 12.20 / 40 | 21300 / 46900 |

| PS-BR-9-12-12-10P | 10 | 2.75 / 9 | 3.65 / 12 | 3.65 / 12 | 9600 / 21000 |

| PS-BR-9-8-20-10P | 10 | 2.75 / 9 | 2.44 / 8 | 6.10 / 20 | 10300 / 225000 |

| PS-BR-9-12-40-10P | 10 | 2.75 / 9 | 3.65 / 12 | 12.20 / 40 | 22700 / 49900 |

| PS-BR-9-20-40-10P | 10 | 2.75 / 9 | 6.10 / 20 | 12.20 / 40 | 33900 / 74700 |

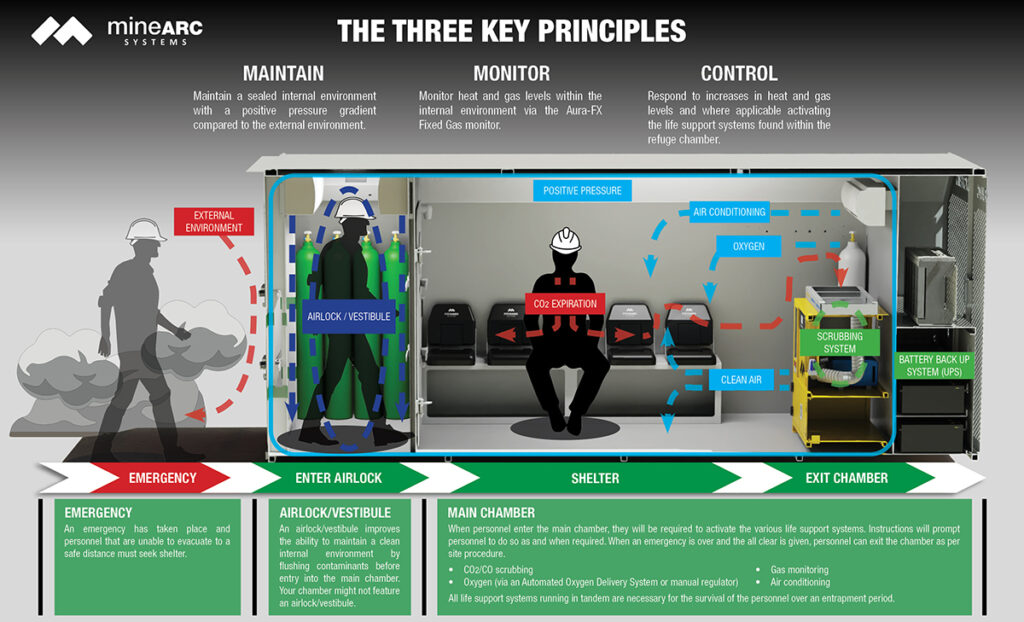

A petrochemical shelter or safe haven is a sealed environment, in which you can take shelter during a hazardous event when evacuation is not possible. These shelters help protect personnel in disasters (fires, explosions, and gas releases), as well as minimise the risk to, and enhance the effectiveness of, emergency responders.

To be classified as a safe haven, a refuge must:

- Be a sealed, enclosed environment with 0% air changes per hour (ACH)

- Provide a source of clean, breathable air by removing carbon monoxide and carbon dioxide from the internal atmosphere and adding in medical grade oxygen

- Control the internal environment, through heating and cooling

- Have a back-up supply of power to support the internal systems if mains power is lost

Petrochemical Safe Havens can be portable, modular, or developed in new or existing buildings. They are purposefully-designed for specific hazards at each petrochemical site.

You may also have heard a Safe Haven called:

- Shelter-in-Place (SIP)

- Protect-in-Place (PIP)

- Refuge Chamber

- Chemical Shelter

- Safe Refuge

- Toxic Gas Refuge

- Temporary Refuge

Comparison Table

- * Capacity Every safe haven is built with a certain rated occupancy in mind. The life support systems are designed to safely house this number of people for the designated duration.

- ** Advanced Digital Control System All safe havens with a Series IV Scrubbing System feature MineARC’s unique Advanced Digital Control System.

- *** iVAN iVAN is an on-board navigation assistant that guides occupants through operational procedures.

- **** Blast Rating MineARC offers blast rating upgrades to all safe havens.

Increasing Blast Effects Comparison

Possible effects on the human body from increasing blast pressure:

Direct Effects

PSI

DESCRIPTION

2.1

Threshold for eardrum rupture

5.1

50% probability of eardrum rupture

7.1

90% probability of eardrum rupture

10

Threshold for internal injuries by blast

12

Threshold for lung haemorrhage

20.1

50% probability of fatality from lung haemorrhage

30

90% probability of fatality from lung haemorrhage

70

Immediate blast fatalities

Indirect Effects

PSI

DESCRIPTION

0.5

Injuries by glass fragments

1.1

Threshold for skin lacerations by missles

1.5

People knocked down by pressure wave

2.1

Possible fatality by being projected against obstacles

4.1

50% probability of fatality from missile wounds

7.1

100% probability of fatality from missile wounds

8.1

People standing up will be thrown a distance

Overpressure Thresholds for Structures and Equipment

PSI

DESCRIPTION

0.2

Threshold for glass breakage

2.2

Collapse of non-reinforced concrete or cinderblock walls

3

Collapse of industrial steel frame structure

5.1

Displacements of pipe bridge, breakage of piping

7.3

Displacement of cylindrical storage tanks, failure of pipes

10.2

Total destruction of buildings, heavy machinery damage

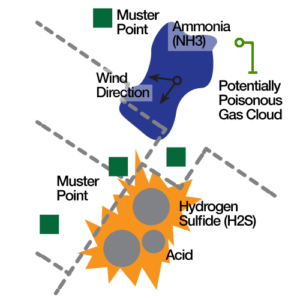

Emergency Management

When evacuation is not possible, Petrochemical shelters provide a safe alternative and are an essential part of emergency management. Shelters should be located in proximity to potential blast or gas release zones.

Refuge Chamber Fundamentals

Case Studies

CSBP Continues its Ammonia Safety Focus with ChemSAFE

This chemical shelter with fixed wheel and tow kit allowed on site personnel to move the safe haven onto the port during ammonia imports.

Custom Central Control Room Shelter for Chlorine Gas Release

Tronox in Kemerton Industrial Park, Western Australia, install custom chemical Safe Haven with remote plant access and chlorine gas monitoring.

Rio Tinto Yarwun Custom Ammonia Chemical Shelters

Rio Tinto in Yarwun, Queensland, install multiple custom refuge chambers to protect from Ammonia gas risks.

Anhydrous Ammonia Release Shelters

The installation of ChemSAFE ammonia release Shelter-in-Place and Safe Havens to protect on-site personnel and provide safe refuge at dedicted Muster Points.

Chemical Shelters For Ammonia Protection at Yara Pilbara Fertiliser Plant

Four 40-person emergency shelters were installed and commissioned at Yara Pilbara Fertilisers. Anhydrous ammonia

Custom Engineered Safe Haven For PetroChina Gasfield

Custom engineering a chemical safe haven with methane and hydrogen sulphide monitoring and scrubbing for PetroChina Oil and Gasfield Southwest Company.