Compressed Air Management System (CAMS)

The Compressed Air Management System (CAMS) is a breathable air system that is unique to the market; offering a range of features aimed at reducing running costs and improving operational safety during an emergency.

Aside from providing clean breathable air through a superior four-phase filtration process, some of the major benefits of CAMS include; optimisation of mine air services, guarantee against over pressurisation of the refuge chamber, gas toxicity monitoring, flood protection, and reduced service time during filter change-out.

All new MineARC Refuge Chambers with compressed air requirements are supplied with CAMS. Currently owned chambers can be upgraded with the CAMS upon request.

- Faster service time

- Flood Protection Valve for automatic mine air shut off in the event of water ingress

- Air toxicity monitoring and emergency shut off valve

- Optimisation of mine air usage, resulting in considerably reduced operational costs

- Security against over-pressurisation

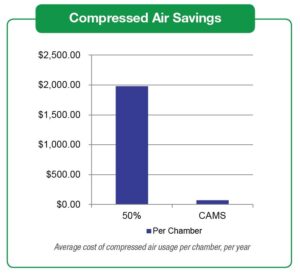

One of the major operational expenses for any mine is the electrical cost of running mine air and air compressors. MineARC Systems identified that by optimising the flow of air required to maintain an operational refuge chamber, we could give our clients considerable savings.

Previously, refuge chambers were set to run at 50% flow rate to maintain operational standard. The new CAMS has an air pressure sensor and shut off valve, allowing it to regulate air flow into the chamber, automatically emitting periodic ‘bursts’ of compressed air when the internal pressure drops below 200Pa. This maintains a positive pressure ‘seal’, ensuring contaminants cannot enter the refuge chamber from the outside.

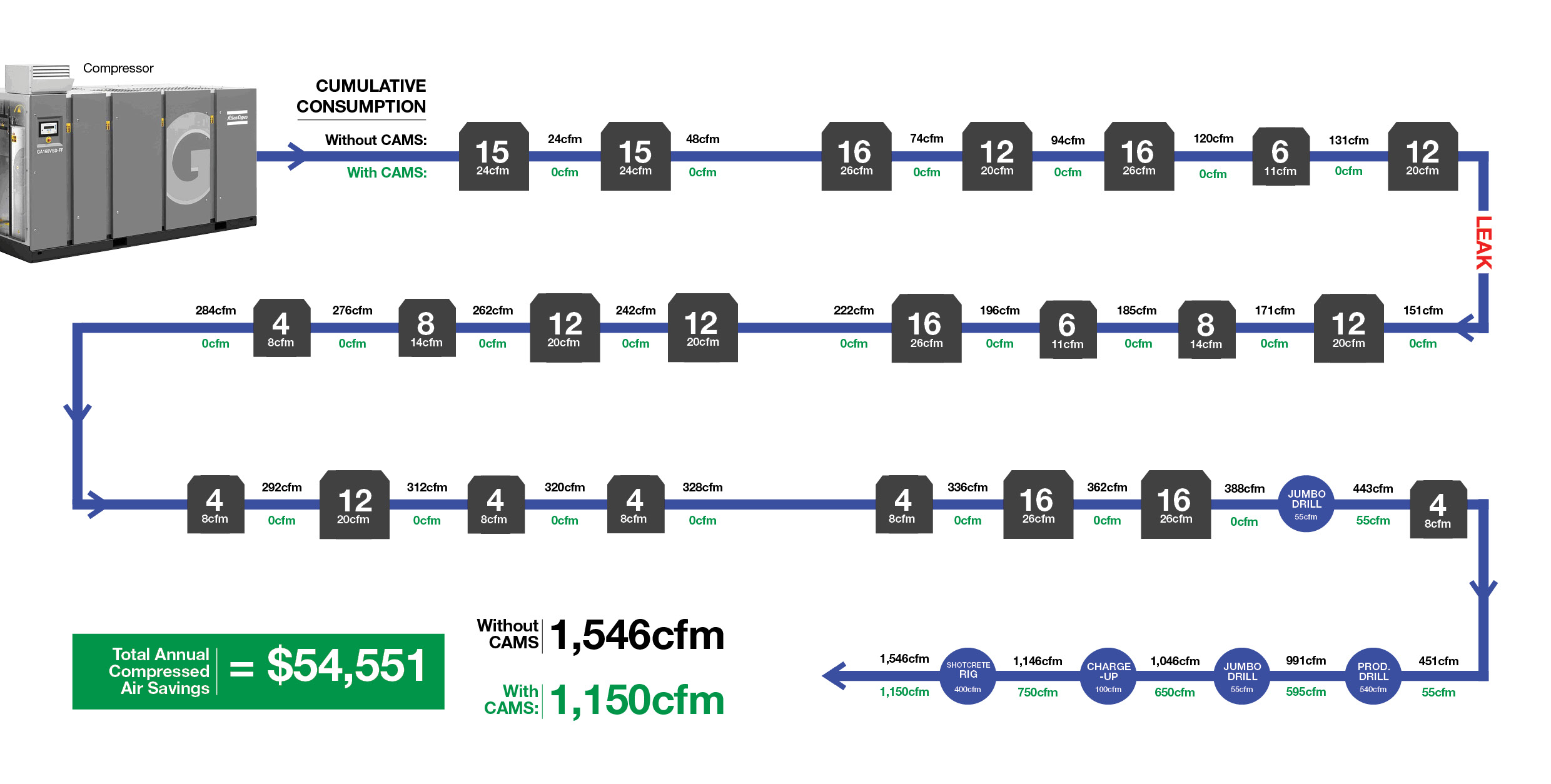

The flow diagram below indicates the path a compressed airline will take before reaching the mine site’s major production requirements. Generally set to run at 50% flow rate to maintain operational standard, refuge chambers put a large strain on compressed air usage. With the inclusion of CAMS, chamber compressed air consumption will fall to 0 CFM for 99% of the time, assuming they are properly sealed.

*Figures based on typical mine site operation. Compressed air flow to refuge chambers set at a conservative 50%. Leaks are hypothetical and could present more frequently. Order of production equipment will vary per mine site.

The CAMS flood protection valve automatically shuts down mine air to avoid catastrophic and costly chamber damage in the event of water ingress. Flooding of a refuge chamber occurs regularly due to human error, either by accidently connecting the water supply to the compressed air intake, or when water infiltrates the mine air supply (the Venturi effect).

The flood protection filter consists of a hydrophobic plastic filter body with a rubber float ball. During periods of significant water flow, the ball will float to the tapered seat and seal shut. Standard mine water pressure will lock the valve shut until the water source is removed and filter water is released via the auto-drain.

The flood protection valve is a pre-existing stand-alone product that is now available as part of the overall Compressed Air Management System at a fraction of the price.

In the case of a mine fire there is a risk that Carbon Monoxide can be drawn through the mine airline, due to a few factors:

• If the compressor is near a fire, it can draw CO and CO2 directly into the mine air

• If the airline is compromised, smoke can be drawn into the airflow due to the Venturi effect

CO is a by-product of incomplete combustion, whether that be compression of smoke at the compressor or the burning of plastic lines before rupture. The gas toxicity monitor automatically diverts mine air if Oxygen levels in the airline fall below a set level (19% oxygen in free air), signifying air contamination. This system detects compressed smoke bursts, where Oxygen is displaced dramatically, rather than sampling low pressure air for slow release contaminants. MineARC’s independent gas monitoring within the chamber will determine slow contaminant build up.

Related Products

Refuge Chamber Monitoring

Refuge Chamber Monitoring Refuge Chamber Monitoring with GuardIAN is an exciting new development in refuge chamber technology. GuardIAN Refuge Chamber Monitoring enables real-time monitoring; providing confidence that an operation’s fleet of refuge chambers are emergency ready at all times. It is an independent system that continuously monitors all vital refuge operating systems. During standby mode, GuardIAN

Aura-FX Digital Gas Monitoring

Aura-FX Digital Gas Monitoring Aura-FX Digital Gas monitoring is an essential aspect of maintaining a life-supporting atmosphere within the refuge chamber. During entrapment, occupants consume oxygen and expire carbon dioxide (CO2) and carbon monoxide (CO) as part of their normal respiration. CO can also enter the chamber during occupant entry and if the compressed air