Multi-Service Vehicle Chamber

– TunnelSAFE MSV Design

Multi-Service Vehicle Chambers are engineered to be mounted to a multi-service vehicle; providing a portable safe haven for tunnelling personnel during routine inspections and maintenance works. As a long term safety option for the entire life of the tunnel, these chambers are robust and fully serviceable.

MineARC’s TunnelSAFE MSV Design Refuge Chamber is highly customisable to suit any tunnelling project and can be built to comply with British Standard (BS EN 16191:2014) Safety Requirements for Tunnelling Machinery or the ITA’s “Guidelines for the Provision of Refuge Chambers Under Construction”.

TunnelSAFE MSV Design Refuge Chambers can also be fitted with remote monitoring systems, or the client’s own remote control system.

- Designed to be mounted on a multi-service vehicle

- Self-regenerative ELV CO and CO2 scrubbing

- Medical O2 regulator and backup

- Positive pressure maintenance system with visual reference

- Aura-FX Digital Gas Monitoring

- Air conditioning and dehumidifying

- 5mm steel plate construction with reflective signage

- Full UPS 24hr battery backup system

- Ergonomically designed seating

- External strobe lighting; internal fluorescent lighting

- GuardIAN Refuge Chamber Monitoring

- Fully Flushing, High Pressure Airlock

- Special Dimensions and Configurations

- Duration Upgrade

- Blast Rating Upgrade

- Blast Shield Protection

- Misting System for External Temperature Control

- Automated Oxygen Delivery System

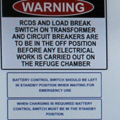

- Step Down Transformer

- First Aid Kit

- Carbon Monoxide Safety-Off-System

Designing Refuge Chambers for Tunnels Under Construction

Monitoring Gas Levels in Tunnelling

Safety Critical for Underwater Tunnel Construction

Combining Transportation and Safety – Riachuelo River Tunnel

Small TBM Strengthens Safety with Custom Refuge Chamber

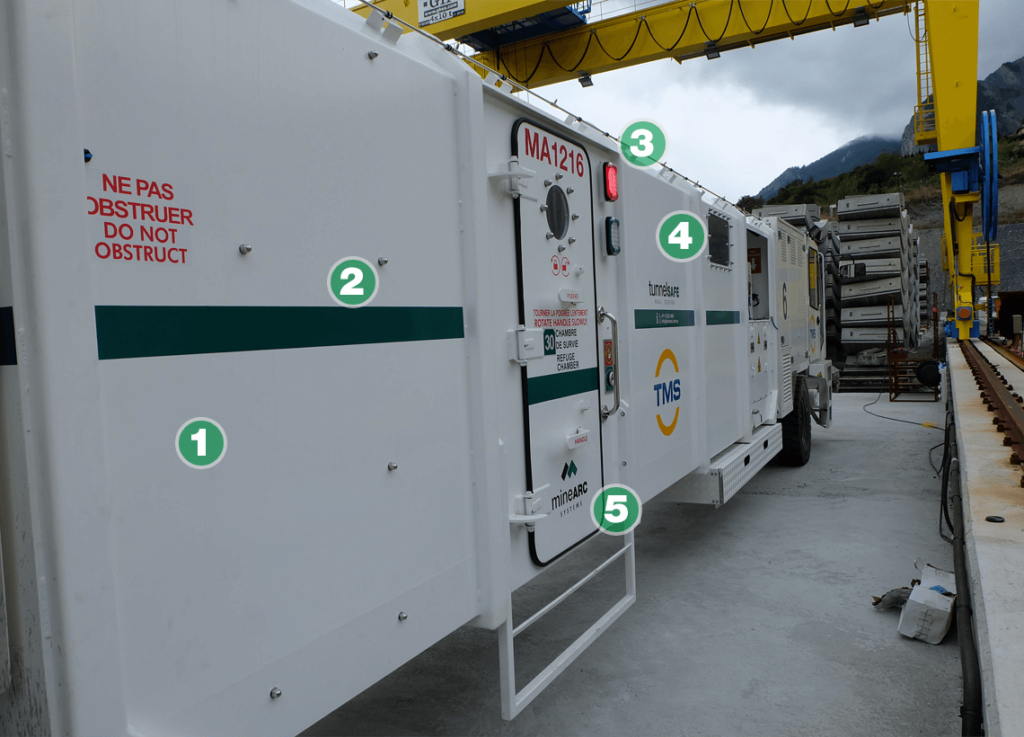

Multi-Service Vehicle Chamber – Front View

The ‘face’ of the refuge chamber is designed primarily for easy identification and quick access during an emergency.

The strobe lighting, warning siren and reflective signage alert passers-by to the chamber’s location, whilst the rotating door handles provide simple, straight forward access to the safety of the interior.

High durability white paint for underground visibility. Sand blasted to 2.5 grit.

High durability white paint for underground visibility. Sand blasted to 2.5 grit. Safety and operational signage in reflective stickering for high visibility underground. Translation into a second language available.

Safety and operational signage in reflective stickering for high visibility underground. Translation into a second language available. Extra low voltage green and red LED lighting to allow for easy identification of the refuge chamber in an emergency.

Extra low voltage green and red LED lighting to allow for easy identification of the refuge chamber in an emergency.

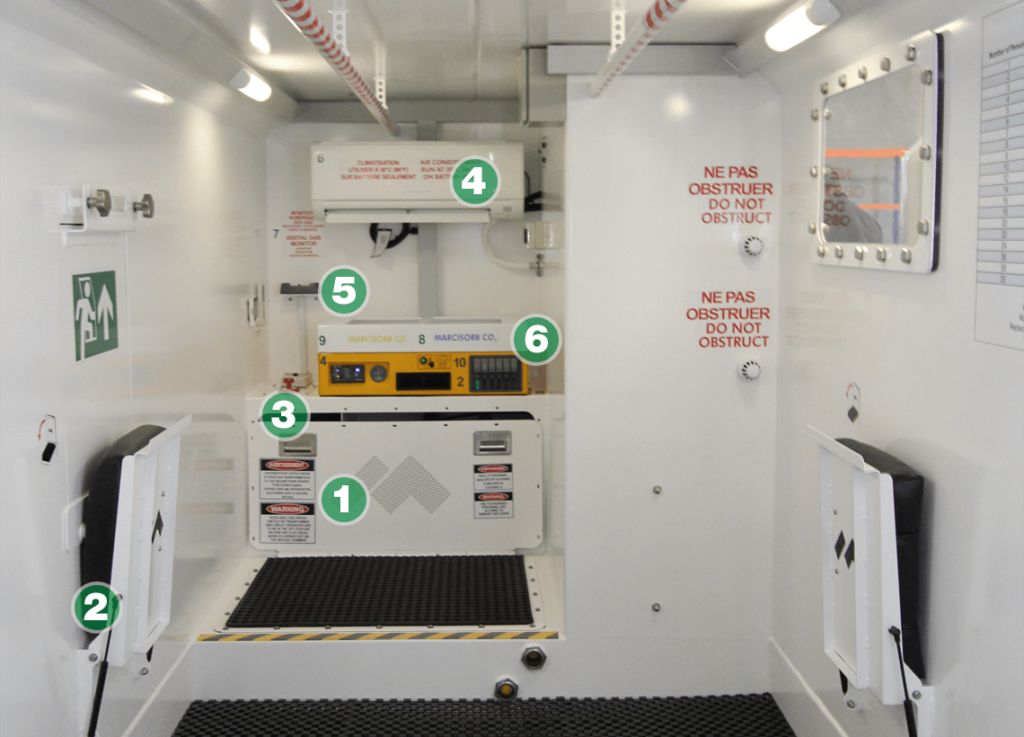

Multi-Service Vehicle Chamber - Interior View

Inside a TunnelSAFE Rail Design Refuge Chamber, a number of vital life-support systems combine to create a safe, ongoing environment for occupants. Systems include; primary and secondary air (oxygen) supplies, air conditioning systems, positive pressure systems, electrical systems, gas detection and a chemical scrubbing system.

The TunnelSAFE Rail Design uses active chemicals and MineARC’s ELV (extra-low-voltage) Scrubbing System to ‘scrub’ the build up of harmful CO2 (carbon dioxide) and CO (carbon monoxide) from the air inside the refuge chamber.

The digital controller interface is the operational hub of the refuge chamber. From here, all power, lighting & scrubbing systems can be managed with the push of a button.

The digital controller interface is the operational hub of the refuge chamber. From here, all power, lighting & scrubbing systems can be managed with the push of a button.