Gantry Mounted Chamber

– TunnelSAFE Gantry Design

Gantry mounted chambers are designed to be installed at the rear of the Tunnel Boring Machine (TBM), providing a fixed safe refuge solution for the life of the tunnelling project.

The TunnelSAFE Gantry Design (GD) is available in a standard and wide design, dependent on the size of the cutting head infrastructure and project requirements.

| Model | Occupancy | Compliance | Height (m) | Width (m) | Length (m) | Weight(kg) |

| TS-GD1-10-ELV-24-I | 10-Person | ITA | 2.00 | 1.60 | 5.60 | 4800 |

| TS-GD3-10-ELV-24-E | 10-Person | BS EN | 2.00 | 1.60 | 7.00 | 5950 |

| TS-GD2-12-ELV-24-I | 12-Person | ITA | 2.00 | 1.60 | 6.30 | 5400 |

| TS-GD4-12-ELV-24-E | 12-Person | BS EN | 2.00 | 1.60 | 7.95 | 6200 |

| TS-GD3-14-ELV-24-I | 14-Person | ITA | 2.00 | 1.60 | 7.00 | 5950 |

| TS-GD5-14-ELV-24-E | 14-Person | BS EN | 2.00 | 1.60 | 9.00 | 6450 |

| TS-GD4-16-ELV-24-I | 16-Person | ITA | 2.00 | 1.60 | 7.95 | 6200 |

| TS-GD6-16-ELV-24-E | 16-Person | BS EN | 2.00 | 1.60 | 9.80 | 6700 |

| TS-GD5-20-ELV-24-I | 20-Person | ITA | 2.00 | 1.60 | 9.00 | 6450 |

| TS-GD8-20-ELV-24-E | 20-Person | BS EN | 2.00 | 1.60 | 9.80 | 7200 |

| TS-GD7-24-ELV-24-I | 24-Person | ITA | 2.00 | 1.60 | 10.50 | 6920 |

| Model | Occupancy | Compliance | Height (m) | Width (m) | Length (m) | Weight (kg) |

| TS-GDW1-10-ELV-24-I | 10-Person | ITA | 2.00 | 2.00 | 4.80 | 4900 |

| TS-GDW3-10-ELV-24-E | 10-Person | BS EN | 2.00 | 2.00 | 5.80 | 5450 |

| TS-GDW2-12-ELV-24-I | 12-Person | ITA | 2.00 | 2.00 | 5.30 | 5200 |

| TS-GDW4-12-ELV-24-E | 12-Person | BS EN | 2.00 | 2.00 | 6.40 | 5900 |

| TS-GDW3-14-ELV-24-I | 14-Person | ITA | 2.00 | 2.00 | 5.80 | 5450 |

| TS-GDW6-14-ELV-24-E | 14-Person | BS EN | 2.00 | 2.00 | 7.75 | 6500 |

| TS-GDW4-16-ELV-24-I | 16-Person | ITA | 2.00 | 2.00 | 6.40 | 5900 |

| TS-GDW7-16-ELV-24-E | 16-Person | BS EN | 2.00 | 2.00 | 8.12 | 6750 |

| TS-GDW5-20-ELV-24-I | 20-Person | ITA | 2.00 | 2.00 | 6.80 | 6150 |

| TS-GDW8-20-ELV-24-E | 20-Person | BS EN | 2.00 | 2.00 | 9.86 | 7300 |

| TS-GDW6-24-ELV-24-I | 24-Person | ITA | 2.00 | 2.00 | 7.75 | 6500 |

| TS-GDW9-24-ELV-24-E | 24-Person | BS EN | 2.00 | 2.00 | 11.40 | 7650 |

- Self-regenerative ELV CO and CO2 scrubbing

- Medical O2 regulator and backup

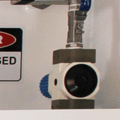

- Compressed Air Management System (CAMS)

- Positive pressure maintenance system with visual reference

- Audio visual warning for pneumatic disruption

- Aura-FX Fixed Gas Monitor

- Air conditioning and dehumidifying

- 5mm steel plate construction with reflective signage

- Water based fire extinguisher (optional for non-Australian orders)

- Full UPS 24hr battery backup system

- Ergonomically designed seating

- Radio power supply

- External strobe lighting; internal fluorescent lighting

- Custom dimensions and transport configurations

- Blast shield protection (reinforced construction)

- Fully Flushing, Pressurised Airlock

- Misting system for external temperature control

- Satellite UPS Systemn

- First aid kit

- GuardIAN Refuge Chamber Monitoring

- Internal LCD monitor screen

- Step-down transformer

- Carbon Monoxide Safety-Off-System (COSOS)

- Remote video camera monitoring

- Intrinsically safe MARCis Scrubber

- Automated Oxygen Delivery System (AODS)

Gantry Mounted Chamber Exterior – Front View

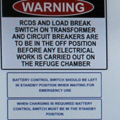

The ‘face’ of the refuge station is designed primarily for easy identification and quick access during an emergency.

The strobe lighting, warning siren and reflective signage alert passers-by to the chamber’s location, whilst the rotating door handles provide simple, straight forward access to the safety of the interior.

Fire blanket with BSI certification (AS/NZ S 3504) located inside chamber.

Gantry Mounted Chamber - Interior View

Inside a TunnelSAFE Gantry Design Refuge Chamber, a number of vital life-support systems combine to create a safe, ongoing environment for occupants. Systems include; primary and secondary air (oxygen) supplies, air conditioning systems, positive pressure systems, electrical systems, gas detection and a chemical scrubbing system.

The TunnelSAFE Gantry Design uses active chemicals and MineARC’s ELV (extra-low-voltage) Scrubbing System to ‘scrub’ the build up of harmful CO2 (carbon dioxide) and CO (carbon monoxide) from the air inside the refuge chamber.