Standalone Uninteruptable Power Supply

MineARC understands the importance of blast protection for personnel working at a petrochemical facility. Third party testing has been performed by professional blast engineers, in accordance with ASCE: Design of Blast-Resistant Buildings in Petrochemical Facilities (2nd).

As part of their in-depth analysis, third-party blast engineers tested the performance of the MineARC Blast Resistant Building, taking into consideration the orientation of the unit with respect to the explosion source. Blasts that can impact either the long or short side of the structure, as well as both sides at an angle were tested.

The results of these studies show that MineARC’s blast resistant structure can withstand a long-duration, free-field blast load of up to 10psi for 200ms.

| Model | Rating (psi) | Height (m/ft) | Width (m/ft) | Length (m/ft) | Weight (kg/lb) |

| PS-BR-9-12-12-1P | 1 | 2.75 / 9 | 3.65 / 12 | 3.65 / 12 | 6300 / 13700 |

| PS-BR-9-8-20-1P | 1 | 2.75 / 9 | 2.44 / 8 | 6.10 / 20 | 6000 / 13100 |

| PS-BR-9-12-40-1P | 1 | 2.75 / 9 | 3.65 / 12 | 12.20 / 40 | 13300 / 29200 |

| PS-BR-9-20-40-1P | 1 | 2.75 / 9 | 6.10 / 20 | 12.20 / 40 | 21300 / 46900 |

| PS-BR-9-12-12-10P | 10 | 2.75 / 9 | 3.65 / 12 | 3.65 / 12 | 9600 / 21000 |

| PS-BR-9-8-20-10P | 10 | 2.75 / 9 | 2.44 / 8 | 6.10 / 20 | 10300 / 225000 |

| PS-BR-9-12-40-10P | 10 | 2.75 / 9 | 3.65 / 12 | 12.20 / 40 | 22700 / 49900 |

| PS-BR-9-20-40-10P | 10 | 2.75 / 9 | 6.10 / 20 | 12.20 / 40 | 33900 / 74700 |

- Engineered steel construction

- ISO container corner castings for transport (stackable)

- Severe environment finish paint

- UV resistant signage

- Closed cell spray foam insulation on all surfaces

- FRP laminated OSB panels for walls and ceiling

- Sealing doors with overpressure relief

- Split system air conditioning/heating system

- Fresh air intake with emergency isolation

- Exposed electrical with tamper proof fluorescent lighting

- Smoke detectors & fire extinguishers

- Aura-FX Gas Monitoring (CO2, O2, Toxic)

- Network Ethernet connections

- GuardIAN Refuge Chamber Monitoring

- AirBANK Pressure System

- AirGEN Scrubbing System

- Oxygen supply

- Blast resistant windows

- Extreme temperature applications (Hyper Heat, R45 insulation, energy recovery ventilation)

- Intrinsic safety for hazardous locations

- Fire resistance (1,100°F/600°C for 30 minutes)

- UPS battery backup on electrical

- External toxic/flammable gas monitoring

- External/Internal vestibule

Click on the video opposite to see the ChemSAFE BRB in the context of a petrochemical facility!

Blast Resistant Building – Front View

The strobe lighting, warning siren and reflective signage alert passers-by to the safe haven’s location, whilst the rotating door handles provide simple, straight forward access to the safety of the interior.

An additional feature of the ChemSAFE Utility Design Toxi Gas Shelter range is a fully pressurised vestibule, providing added protection against the ingress of smoke and other harmful toxins. Vestibules are available as either an internal or external feature of the safe haven. See further on for additional information.

Corner castings for transport and stacking

Sealing door with overpressure relief.

Engineered steel construction with closed cell spray foam insulation on all surfaces.

Sand blasted to 2.5 grit. Severe environment finish paint, resistant to weather and corrosion. UV resistant signage.

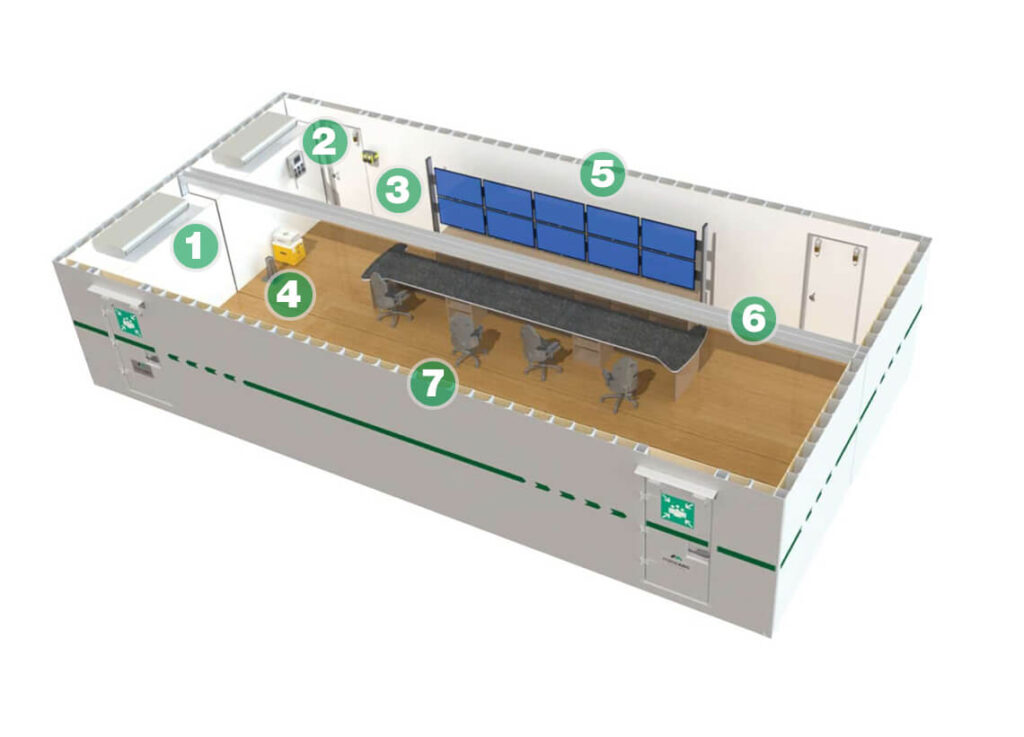

Safe Haven - Interior View

Inside a ChemSAFE Utility Design Safe Haven, a number of vital life-support systems combine to create a safe, ongoing environment for occupants. Systems include; air (oxygen) supplies, air conditioning and dehumidifying, positive pressure systems, electrical and communications, gas detection and carbon dioxide removal.

MineARC’s ELV (extra-low-voltage) System comes as standard with the ChemSAFE Utility Design. The ELV Control System can be installed in conjunction with an optional UPS battery backup that can power the system for a minium of 12hrs, should mains power be cut off.

Split system air conditioning and heating.

AirBANK Pressure System

Aura-FX Gas Monitoring (CO2, O2 and toxic gases).

AirGEN Scrubbing and oxygen supply.

Network Ethernet connections.

Tamper proof fluorescent lighting, smoke detectors and fire extinguishers.

FRP laminated OSB panels for walls and ceiling.

Safe Haven Exterior - Rear View

The rear of the ChemSAFE Utility Design houses important electrical and backup power supply systems. An optional feature of the toxic gas shelter is a UPS (Uninterruptible Power Supply) battery backup system, contained within a secure rear cabinet. The UPS is a failsafe system that can power the safe haven’s internal life support systems for a minimum of 12hrs, should mains power become cut-off.

Optional: Emergency backup power supply.

Split system air conditioning and heating.Extreme temperature options available including Hyper Heat, R45 insulation, energy recovery ventilation).

CHEMSAFE REFUGE CHAMBER COMPARISON TABLE

| Capacity * | Advanced Digital Control System ** | iVAN *** | Aura-FX Gas monitoring | Vestibule | Shelter-in-Place | 12hrs Battery Backup | Blast Rating **** | |

| 8-30 | 5 psi | |||||||

| 8-30 | 5 psi | |||||||

| CUST | 1-10 psi | |||||||

| CUST | 5 psi |

- * Capacity Every safe haven is built with a certain rated occupancy in mind. The life support systems are designed to safely house this number of people for the designated duration..

- ** Advanced Digital Control System All safe havens with a Series IV Scrubbing System feature MineARC's unique Advanced Digital Control System.

- *** iVAN iVAN is an on-board navigation assistant that guides occupants through operational procedures.

- **** Blast Rating MineARC offers blast rating upgrades to all safe havens.