Shelter-in-Place - ChemSAFE Sealed Rooms

- Custom modular construction

- ACH < 0.1

- 3" fiberglass reinforced plastic covered gypsum on exterior and interior with a polystyrene center

- Electrical package consisting of lights and outlets

- Integrated MineARC life support options

Shelter-in-Place Integrity Testing

Understanding the present leak rate can determine the best course of action moving forward. Allowing you to explore your available options; whether remediation and structural works to seal off the space or where a building is concluded to be impractical to convert, provide external safe rooms.

Understanding the present leak rate can determine the best course of action moving forward. Allowing you to explore your available options; whether remediation and structural works to seal off the space or where a building is concluded to be impractical to convert, provide external safe rooms.

MineARC Systems have the testing ability in-house that allows us to establish baseline integrity readings and provide a greater indication of your current level of protection against ingress.

Our integrity testing system is engineered to be portable and able to travel to individual sites for verification and auditing purposes and is ideal for generating an accurate baseline position for risk assessment.

Contact MineARC to have your site tested.

Click on the video opposite to see the ChemSAFE Sealed Room in the context of a petrochemical facility!

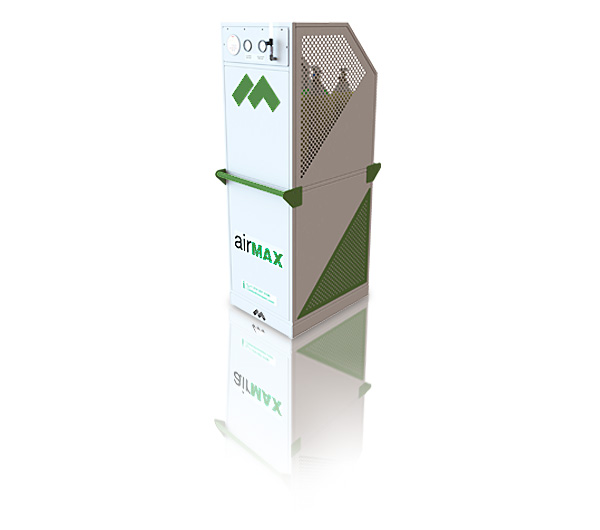

AirMAX Life Support

Non-built-for-purpose buildings in petrochemical facilities generally do not meet acceptable leak tightness for shelter-in-place. With ventilation shut down, a typical building can have up to five air changes per hour or higher depending on wind speed. Door operation as people enter can potentially bring additional contaminants from outside the shelter. As contaminated air infiltrates a petrochemical building, the level of protection provided to the occupants diminishes with time. A safer and more economical alternative is to seal smaller existing rooms within a larger building.

There are cost-effective means to create a pressurised shelter or ‘very tight’ room.

The MineARC AirMAX Life Support System combines two critical life support features. A Positive Pressure Maintenance System (PPMS) to keep toxic and hazardous gases out, and a supplemental oxygen delivery system to replenish the air. Optional Aura-FX Gas Monitoring ensures that external contaminants cannot enter the sealed room, while alerting users to changes in gas levels.

There are cost-effective means to create a pressurised shelter or ‘very tight’ room.

The MineARC AirMAX Life Support System combines two critical life support features. A Positive Pressure Maintenance System (PPMS) to keep toxic and hazardous gases out, and a supplemental oxygen delivery system to replenish the air. Optional Aura-FX Gas Monitoring ensures that external contaminants cannot enter the sealed room, while alerting users to changes in gas levels.- Mobile design for easy relocation

- Oxygen and compressed air cylinder storage

- Oxygen Delivery System

- Positive Pressure Maintenance System (>0.14psi)

- 120/240V electrical connection

- Optional Aura-FX Gas Monitoring (NH3, CL etc.)

- Occupancy: 4 Hours

- Voltage: 120V or 240V

- Depth: 36.25in (0.92m)

- Width: 25.25in (0.62m)

- Height: 76in (1.93m)

- Weight (Est.): 1,100lbs (500kg)

AirBANK Pressure System

A critical requirement for any petrochemical shelter-in-place location is maintaining internal positive pressure in order to prevent the ingress of toxic and hazardous gases resulting from an accidental chemical release. MineARC’s AirBANK Pressure System offers a simple modular solution; ensuring occupants remain safe inside of a designated pressurised shelter for a specified duration.

AirBANK provides rapid pressurization, which is activated and maintained using the AirBANK CONTROL via a simple HMI touch screen. MineARC’s integrated Aura-FX Gas Monitor ensures breathable air remains within acceptable limits. Alternatively, ChemSAFE Sealed Rooms can be fitted with supplementary oxygen and carbon dioxide scrubbing systems.

AirBANK provides rapid pressurization, which is activated and maintained using the AirBANK CONTROL via a simple HMI touch screen. MineARC’s integrated Aura-FX Gas Monitor ensures breathable air remains within acceptable limits. Alternatively, ChemSAFE Sealed Rooms can be fitted with supplementary oxygen and carbon dioxide scrubbing systems. The AirBANK Pressure System is designed to store 11 4,500psi or 6,000psi cylinders, and allows any number of cylinder racks to be daisy-chained as required. Each rack is leak protected by a check valve and electric solenoid, and features a panel mounted gauge to display the high and low pressure level of the unit.

The AirBANK Pressure System is designed to store 11 4,500psi or 6,000psi cylinders, and allows any number of cylinder racks to be daisy-chained as required. Each rack is leak protected by a check valve and electric solenoid, and features a panel mounted gauge to display the high and low pressure level of the unit.AirBANK CONTROL features an active by-pass of the system if internal gas levels are not within breathable air limits. The Aura-FX monitors and displays gas levels in real-time, including site-specific toxic gases if necessary.

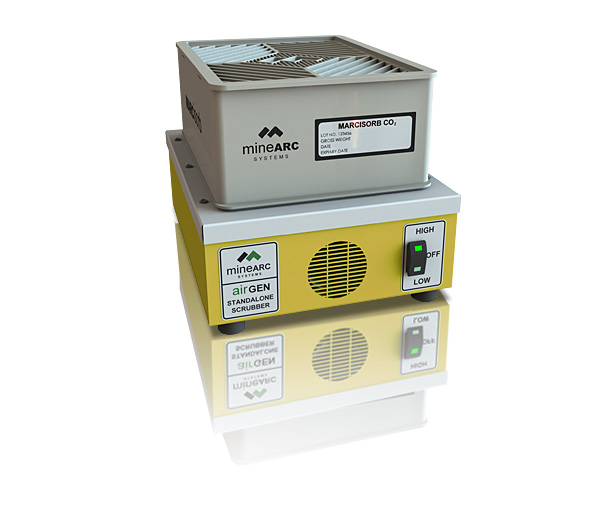

AirGEN Scrubbing System

Depending on the designated occupancy of the petrochemical facility’s sealed room location and volume, CO2 removal may be required. The MineARC AirGEN is a standalone air regenerative system that ‘scrubs’ the air inside of an enclosed location, effectively cleaning it so occupants can breathe.

Humans consume oxygen and expire carbon dioxide (CO2) as part of normal respiration. In high enough concentrations, CO2 can cause serious injury, leading to a loss of consciousness and eventually death. Removal of CO2 is therefore a vital necessity for any shelter-in-place location, especially where CO2 concentrations exceed one percent over the entrapment duration.

The AirGEN is simple to operate with only a single switch and is powered from its own internal battery supply.

Comparison Table

| Capacity * | Advanced Digital Control System ** | iVAN *** | Aura-FX Gas monitoring | Vestibule | Shelter-in-Place | 12hrs Battery Backup | Blast Rating **** | |

| 8-30 | 5 psi | |||||||

| 8-30 | 5 psi | |||||||

| CUST | 1-10 psi | |||||||

| CUST | 5 psi |

- * Capacity Every safe haven is built with a certain rated occupancy in mind. The life support systems are designed to safely house this number of people for the designated duration..

- ** Advanced Digital Control System All safe havens with a Series IV Scrubbing System feature MineARC's unique Advanced Digital Control System.

- *** iVAN iVAN is an on-board navigation assistant that guides occupants through operational procedures.

- **** Blast Rating MineARC offers blast rating upgrades to all safe havens.