Modular Cleanrooms - Biora

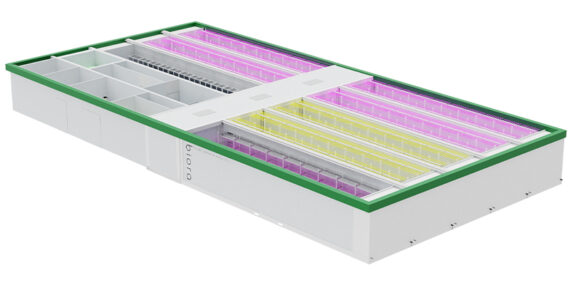

Modular cleanrooms by Biora offer the most flexible and versatile way of designing a “room within a room” for high environmental control. They cater to applications including manufacturing, scientific research, pharmaceutical and medical.

Biora Cleanrooms (also known as clean rooms or clean spaces) are engineered and manufactured to meet your unique conditions and required standard. With a range of established sizes and made-to-order designs to fit your application and configurations needs.

With decades of controlled environment expertise and a global support network, Biora cleanrooms are of the highest quality. Our leading team will guide you through cleanroom design, installation, and maintenance, ensuring your critical environment needs are met. Delivering you a purpose-built cleanroom to protect people, product, and the environment.

- Medicinal cannabis production

- General laboratory facilities for testing or research purposes

- Product inspection facilities

- Pharmaceutical and Medical grade production facilities

- Storage and containment of sensitive materials

- Electronics, semi-conductor, and high-tech manufacturing

- Food processing, testing and development

- Industrial manufacturing and design

- Anywhere a high degree of biosafety and containment is needed

Modular options that allow expansion over time

Multi-room or zone options based on requirements

Specialised temperature and humidity control

Cleanroom-grade insulated external panelling

Clean-room grade internal panelling, designed to withstand cleaning chemicals and agents

Heavy-duty, bio-security, anti-static vinyl flooring

99.99% HEPA filters

Concealed ducting and electrical within ceiling – accessible via external panels

Coved joints and right-angle corners to prevent settling of dust

Drop seal on doors, with a positively pressurised interior; preventing contamination ingress

Rugged external structure, allowing manoeuvrability and placement outdoors

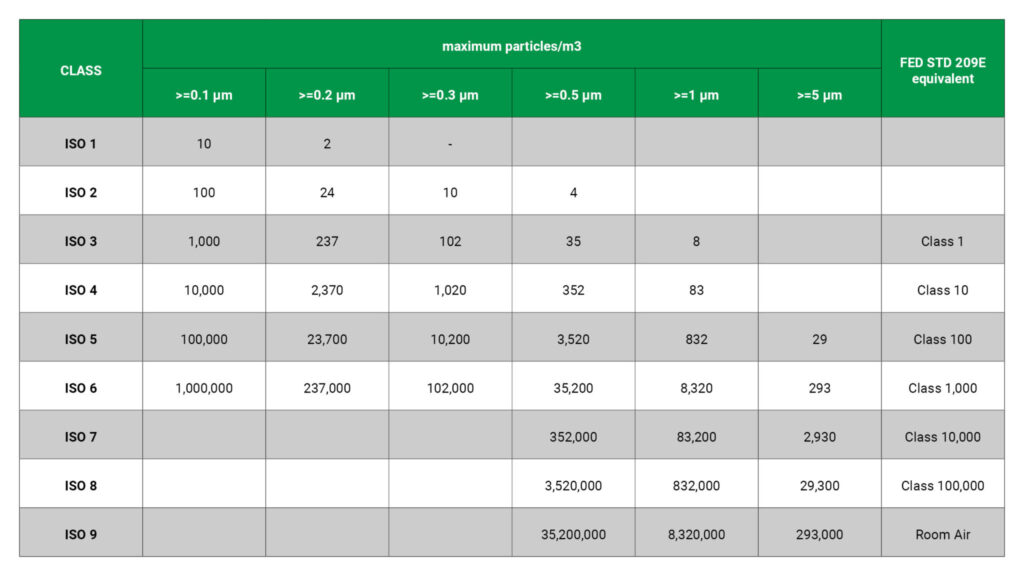

ISO 14644-1 Cleanroom Standards

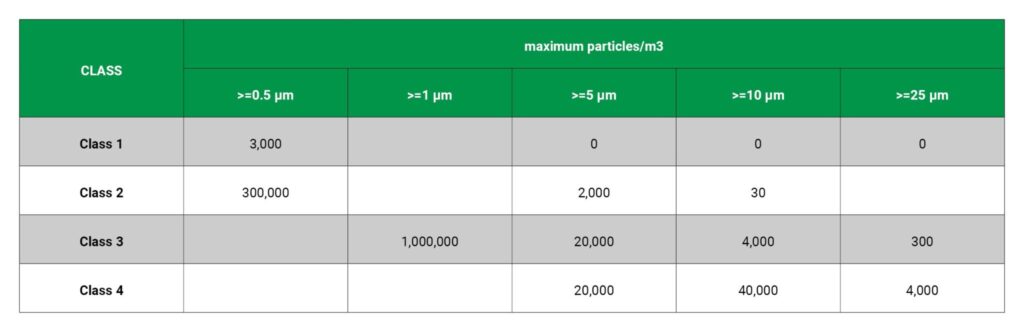

BS 5295 Cleanroom Standards

Biora manufacturers and designs a range of cleanroom models that can comply with various standards and classes, including:

- ISO 14644-1

- GMP EU

- British Standard 5295, BS EN ISO 14644-1

- Therapeutic Goods Association

Modular Cleanroom Solutions

Modular style cleanrooms are the most flexible and versatile way of designing a “room within a room”.

Biora’s flat-pack, prefabricated panel systems are engineered to fit within an existing space, ideal for research that requires a fast and easy to install solution with minimal on-site disruption. The prefabricated panel design offers the ability to relocate or expand the cleanroom with future developments.

Join multiple cleanrooms to create a system of interconnected rooms or facilities.

The linked system revolves around our specialised “Flange Connection System” to ensure an air-tight seal while at the same time maintaining the integrity of each cleanroom. The individual units can be set up with a centralised or independent HVAC system, allowing you to run each cleanroom independently for operational redundancy.

Support strict decontamination processes of people or equipment with purpose-built facilities and attachments.

Decontamination cleanrooms, whether prefabricated or portable, attach to existing cleanrooms or physical containment facilities. These structures allow for large equipment within the laboratory that cannot be removed by autoclave or a similar, to be cleaned.

Additional equipment, including airlocks and prebuilt purge chambers, provide a physical barrier between the laboratory and the outside environment. Options include a positive or negative pressure environment and the ability to monitor and purge various gasses such as CO2 or a de-containment agent (deployed through a fogging system).

Cleanroom Technology

Controlling and managing the concentration of airborne particles and relevant environmental parameters requires precise construction and high-quality systems. During the design and construction of Biora cleanrooms, quality control focuses on several crucial features that support minimal contamination.

To achieve a particular cleanliness specification, all surfaces in a cleanroom are smooth and impervious, and:

- Does not generate its own contamination (create dust, flake, corrode, or provide a place for microorganisms to propagate)

- Are easy to clean (accessible and do not feature ledges or recesses)

- They are rigid and robust and will not crack or dent easily

Biora Cleanrooms are built with heavy-duty, anti-static, biosecurity vinyl flooring. It is resistant to most decontamination agents and chemical cleaners, ensuring longevity and allowing the room to be thoroughly cleaned. Additionally, coved joints and right-angle corners prevent dust and dirt from settling on the internal surfaces.

MineARC Systems Engineers will work closely with you to specify the most suitable type of internal surface materials for your project.

HEPA (High-Efficiency Particulate Air) filters are a critical element of any cleanroom. They consist of a large, box-shaped filter that effectively removes airborne particles of specific sizes. Particles become trapped through a combination of the following three mechanisms:

- Diffusion

- Interception

- Impaction

Filters meeting the HEPA standard must satisfy certain levels of efficiency. Biora Cleanrooms aim for a 99.99% HEPA filtration. Common standards require that a HEPA air filter remove a minimum of 99.95% of foreign particles with a diameter equal to 0.3 μm from passing air. The filtration efficiency requirement increases for particle diameters both less than and greater than 0.3 μm.

Biora can provide additional service and maintenance support for critical cleanroom componentry such as HEPA Filtration and HVAC systems. While the intelligent HMI continually monitors the systems, sending push notifications for regular testing and alerts.

Biora’s industry-leading control system allows for intuitive programming and remote, web-based management. Enjoy real-time monitoring of all control processes, with the ability to access 12 months’ worth of historical data.

The high-resolution touch screen has a user-friendly display and navigation. Chamber status, historical data, alarms, and programming can all be accessed and controlled via the HMI. Plus, customised security levels ensure your research is kept safe and secure.

- Web-based software with both local and remote access

- Real-time monitoring of all control processes

- 12 months of historical data accessible

- Limitless customisable programs

- Data export and import options

- Push notifications based on custom alert settings

- Data protection and security options

- Customised HMI options and local engineering support

Besides its remote capabilities, Biora’s Control System is accessible via a touch-screen HMI Panel located on the face or inside each Biora Cleanroom.

Controlling the volume of air introduced and removed from portable and modular cleanrooms is critical to its design. Cleanrooms operate at a higher pressure compared to the external atmosphere to prevent the ingress of contaminants.

MineARC Systems are experts in the manufacture of controlled environments, with over 20 years of experience providing positive pressure chambers. As such, the positively pressured interior of any Biora Cleanroom will confidently protect the internal atmosphere from any contamination in conjunction with airlock and door drop seal technology.

Related Products

Camera Lens Filters – Biora Method Seven

Camera Lens Filters – Biora Method Seven With Biora’s range of LED and HPS Camera Lens Filters, you can capture amazing, perfect colour photos and videos inside your grow room. Specially formulated photo filter lenses balance light output of popular LED and HPS lights. Biora camera filters are housed in anodized aluminium and compatible with

HPS Glasses – Biora Method Seven Eyewear

HPS Glasses – Biora Method Seven Eyewear Biora’s HPS Glasses for grow rooms, designed by Method Seven, feature unique mineral glass lenses that deliver perfect colour balancing in the intense yellow spectrum and harsh visual conditions of HPS lighting environments. Tuned and tested for grow environments, Biora Method Seven HPS eyewear is available in a

LED Glasses – Biora Method Seven Eyewear

LED Glasses – Biora Method Seven Eyewear LED Glasses for grow rooms, designed by Method Seven, deliver the world’s first glasses formulated to light balance and compensate for the unique spectrum of LED grow lights. Unique LED lens technology and highest quality materials provide exceptional colour and clarity, as well as 100% UV protection. This