A refuge chamber chemical scrubber removes undesired gases from the air using chemical reactions. Changing the composition of the gas to water and heat as they pass through the system.

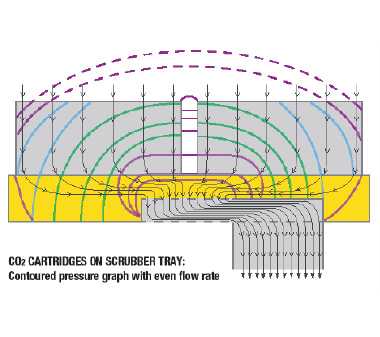

Equal and even pressure supports efficient chemical reactions, ensuring the refuge chamber’s performance characteristics are optimised.

But what are the fundamental differences between free pour chemical and chemical cartridges for scrubbing within a refuge chamber?

The Science Behind Refuge Chamber Scrubbing Systems

Scrubbing systems work in conjunction with active chemicals to ‘scrub’ the build-up of harmful gases such as carbon monoxide (CO) and carbon dioxide (CO2) from the air inside the refuge chamber. During entrapment, occupants consume oxygen and expire CO2 and CO as part of their normal respiration. CO can also enter the chamber during occupant entry and if the compressed air intake is compromised. In addition, CO2 can build up and poison the air causing several symptoms, including visual and hearing dysfunction, unconsciousness and eventually, death. Therefore, removing these harmful gases is a vital necessity for any refuge chamber, especially if mains air fails or becomes compromised.

Pressure and Airflow in Chemical Scrubbers

Equal and even pressure will result in an effective rate of the chemical reaction. The scrubbing equipment, including plenum trays, must evenly distribute air pressure and flow throughout the scrubbing material, ensuring the chemical’s optimal performance. This allows for a standard duration of 36 hours (required by the 2013 WA DMP Guidelines: Refuge Chambers in Underground Mines). Any variant of these characteristics will result in a shortened refuge chamber duration.

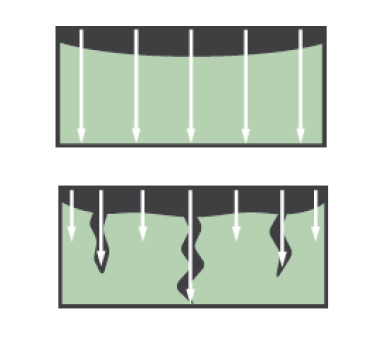

If there are high-pressure pockets in the plenum tray or defects in the chemical bed, the chemical will ‘channel’. This is where the air follows the path of least resistance and will drastically reduce the material’s efficiency and effectiveness, ultimately reducing duration. In some cases, this reduction can be as high as 60% (14.4 hours).

Refuge Chamber Scrubber Chemical Size and Shape

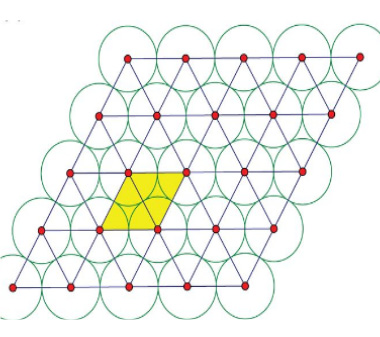

The scrubbing material itself is also critical. It’s size and shape create a packing density matrix that requires a specific flow and pressure differential to ensure it is effective.

Variants of density will impact the efficiency and ultimate duration of this breathing source. Any changes to the chemical or the equipment would require calculations to ensure that it can remove CO2 and CO in the chamber over the entire duration of entrapment as a life support system.

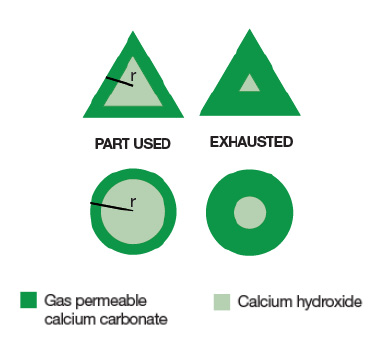

A non-minearc chemical is usually a different shape, most commonly a diver-grade spherical granule. MineARC’s material is a crushed triangle with greater efficiency and allows for more material to be stored within the same volume.

A tightly packed volume requires a specific pressure and flow to achieve the appropriate rate of reaction. Any variants in this will reduce efficiency and therefore duration.

As you can see below, a triangle granule allows more consumption of material before exhaustion. The area of the triangle is less than the circle with the same wall thickness. Using the circular material immediately reduces the amount of chemical you have available to you in that volume, which means less duration.

Packed together, the circles have more space between them than the triangles. Packed down triangular particles inhibit channelling – where air flows through gaps as a path of least resistance and doesn’t use the chemicals around it.

Understanding Free Pour Chemicals for Refuge Chambers

‘Free Pour Chemical’ is a more manual method to scrub the air within a refuge chamber of harmful gases.

It consisted of three different chemical types that would be opened and poured into associated trays in varying quantities.

The three types of free pour chemical included:

- CO2 chemical often referred to as Medisorb, Sofnolime or Sodalime

- CO chemical often called Sofnocat

- A moisture removal chemical

How MineARC Refuge Chambers Used Free Pour Chemical

Free Pour chemical scrubbers were fitted as standard for MineARC’s Hard Rock Mining Series I, II, and III Refuge Chambers.

Each refuge chamber required twelve 10kg tubs of moisture removal chemical, six 1kg tubs of CO chemical, and depending on the occupancy, the following amount of 4.5kg CO2 chemical containers:

- 8-Person = 18

- 12-Person = 26

- 16-Person = 32

- 20-Person = 44

Understanding Cartridge Chemicals for Refuge Chambers

Chemical Cartridges in scrubbing systems use fitted containers with a prepackaged chemical to help remove harmful gases within the shelter.

MARCISORB CO2 and MARCISORB CO chemical cartridges provide superior scrubbing capacity, are easy to load, safe to handle, and store for long periods.

Use of the chemical cartridge also translates to noticeable cost savings over the chamber’s life compared to free pour methods.

How MineARC Refuge Chambers Used Cartridge Chemical

Series IV and ELV/ELVP Scrubbing Systems use pre-packaged MARCISORB chemical absorber cartridges, an improved alternative to the traditional free pour chemicals found in earlier scrubbing system models.

Each refuge chamber requires just one 15kg MARCISORB CO chemical cartridge and the following quantities of 15kg MARCISORB CO2 cartridges:

- 8-Person = 8

- 12-Person = 10

- 16-Person = 14

- 20-Person = 16

The Benefits of the Chemical Cartridge

Fewer units of chemical required, more room in the chamber

Unlike earlier free pour methods that require three separate chemicals, MARCISORB Chemical Cartridges feature an inbuilt moisture removal capability. This means that the overall quantity of chemicals required by the chamber is significantly reduced.

Less manual handling, no direct chemical handling

As fewer chemical quantities are required, there will be a reduced need for manual handling to transfer the chemical to the scrubber trays. The cartridge chemical is contained in spill-proof and compact plastic cartridges, with no need for workers to come into direct contact with the chemical itself.

Less uncertainty, no room for user error

Reduced uncertainty with how many chemicals should be used, with accurate chemical amounts efficiently distributed inside each of the pre-packaged cartridges.

Conformity across refuge chamber fleet

All of MineARC’s refuge chambers now come with MARCISORB cartridge chemical as standard. Using one type of chemical scrubbing system assists in streamlined training and purchasing processes.