Tunnelling Construction Safety Solutions

MineARC specialises in the manufacture and supply of safety solutions for the tunnelling industry including civil engineering companies and tunnelling contractors.

As members of the International Tunnelling Association, we have engineered a series of refuge chambers that fully comply with the ITA ‘Guidelines for the Provision of Refuge Chambers in Tunnels Under Construction’.

We also have the capacity to build tunnel-specific refuge chambers which comply with the European Standard (EN 16191:2014) Safety Requirements for Tunnelling Machinery and British Standard (BS 6164:2011) Code of Practice for Health and Safety in Tunnelling in the Construction Industry.

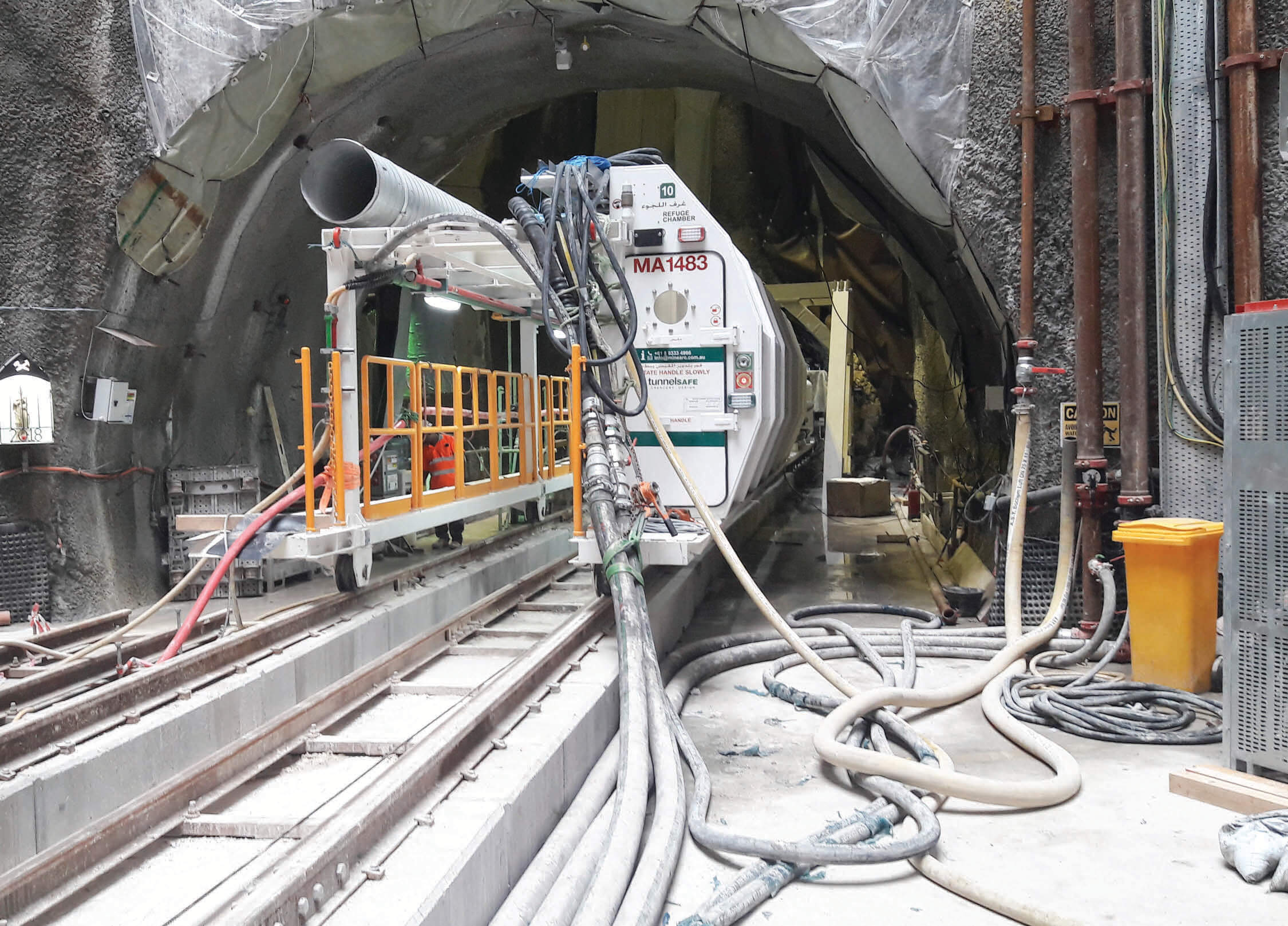

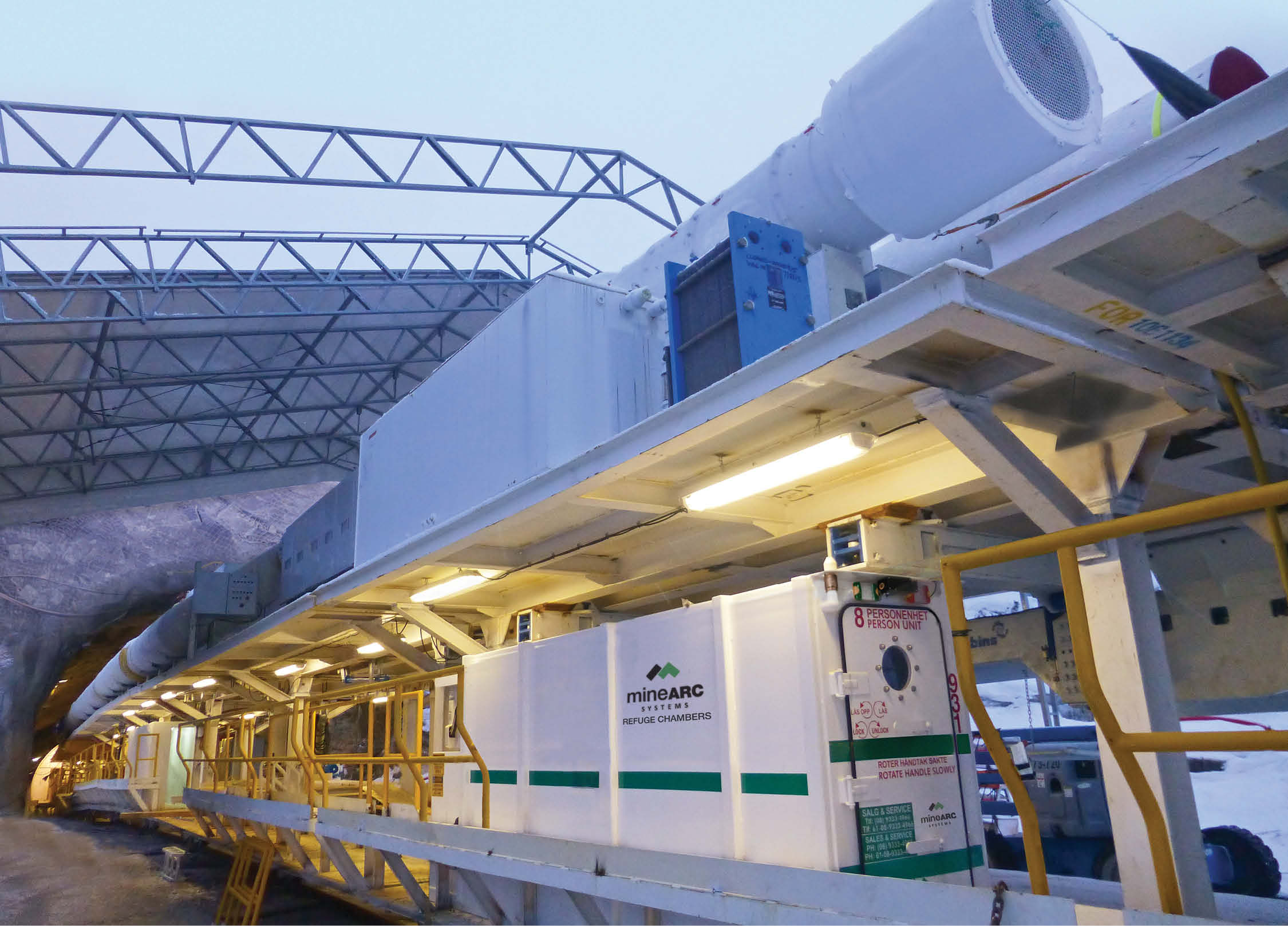

Our extensive range of TunnelSAFE Refuge Chambers offer a solution for every application and requirement; from Tunnel Boring Machine (TBM) gantry-mounted designs, to mobile rail models, to transportable drill and blast units. With a suite of complementary safety products and our state-of-the-art GuardIAN Intelligence range, MineARC can provide any tunnelling project a fully integrated emergency response solution.

Emergency refuge forms an integral part of a tunnelling project’s wider Emergency Response Plan (ERP). Fires, fall of ground, and the release of smoke and other forms of toxic gas are the types of incidents that can occur all too frequently, despite the high levels of planning and safety precautions in place.

In these types of emergencies, where personnel become trapped without adequate ventilation and evacuation is no longer safe or practical, emergency refuge chambers are designed to provide a secure ‘go-to’ area for personnel to gather and await extraction.

TunnelSAFE Refuge Chambers are designed for various applications; including a TBM mounted ‘Gantry Design’, the highly mobile Rail and MSV Designs and a range of highly portable Drill and Blast Chambers that can be repositioned with ease.

TunnelSAFE Chambers come in all shapes and sizes; such as ‘Crescent’ or ‘Micro’ designs for projects with space constraints on the gantry. MineARC’s tunnelling chambers can be fitted with remote monitoring systems or a client’s own control system, as well as to custom specifications depending on requirements.

Industry Impact

GuardIAN Intelligence Network

In response to industry requirements, the GuardIAN Intelligence Network has been designed to improve personnel safety, increase productivity and provide greater cost efficiencies to sites globally.

It has been engineered to provide site-wide integration; allowing real-time monitoring of the construction environment, site assets, and personnel via any PC, tablet or mobile device.

GuardIAN encompasses a range of products that can be implemented singularly or collectively to improve safety standards on-site, including gas monitoring, smart lighting, personnel tracking and refuge chamber monitoring.

Waste Management for the TBM Industry

MineARC’s award winning EnviroLAV Waste Management System can be easily positioned at the rear of the TBM gantry, allowing for quick and simple installation and service on site.

The Compact model EnviroLAV features a small footprint of less than 1.5m2; an ideal size for the tight confines of the TBM where space is a limiting factor. Removable steps allow for further maximisation of space.

The EnviroLAV’s unique waste breakdown process reduces emptying requirements to just once per year based on standard usage and environmental conditions; providing significant cost savings throughout the life of the tunnelling project.

SiriUS Cap Lamp Range

MineARC offers a range of LED Cap Lamps, designed to improve visibility across a range of activities including underground mining, tunnelling, emergency response, and leisure.

With corded and cordless models available across the range and charging racks to suit, MineARC cap lamps provide a quality and reliable lighting solution.

Latest News

Gas Monitors For A Tunnelling Refuge Chamber

Gas monitors for a tunnelling refuge chamber allows occupants to measure levels in and outside of a chamber and taking corrective action to maintain a safe environment.

A Guide to Selecting the Best Tunnelling Toilet [Infographic]

A checklist of 12 critical points to help you select the best industrial toilet for tunnelling works and underground construction projects.

A Guide to Selecting the Best Portable Mine Toilet [Infographic]

A checklist of 12 critical points to help you select the best portable toilet for an above or underground mine.